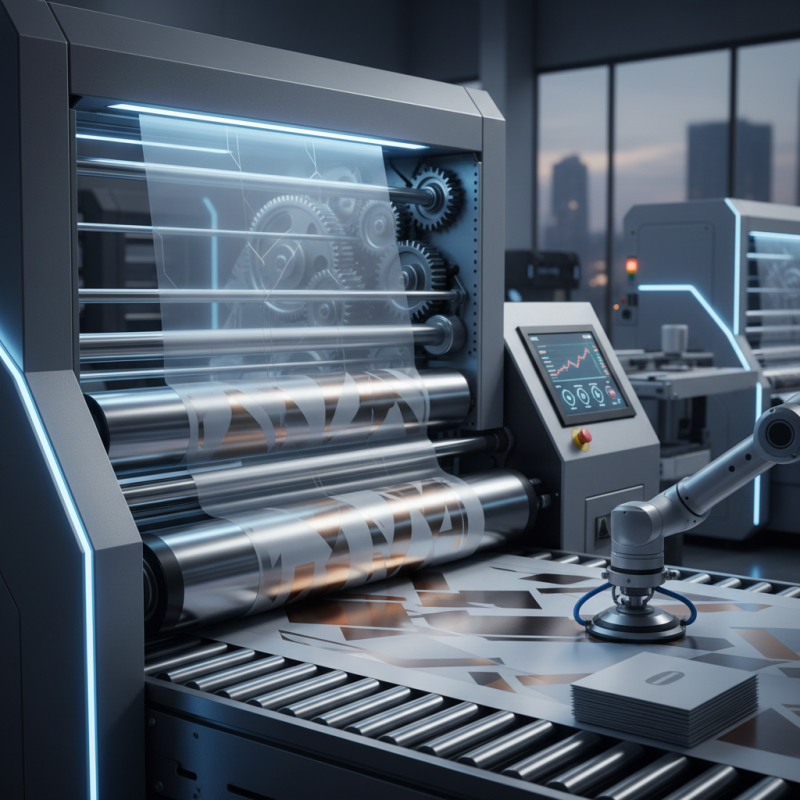

2026 Best Roll Lamination Machine Features and Benefits?

In the fast-evolving world of manufacturing, the "Roll Lamination Machine" has emerged as a pivotal tool across various industries. According to a recent report by Market Research Future, the global roll lamination market is projected to grow by 7% annually until 2026. This growth highlights the increasing need for efficient lamination solutions. Such machines enhance product durability and aesthetic appeal, crucial factors in sectors like packaging and print.

Efficiency is not the only metric to consider. Although this technology streamlines production, challenges such as maintenance costs and machine calibration persist. Ensuring optimal performance requires a deep understanding of the equipment's specifications. Modern roll lamination machines offer features like adjustable speed settings and temperature controls, yet not all users maximize these options. Some fail to recognize the importance of training staff on these advanced features.

Investing in the right roll lamination machine can yield significant benefits. A quality machine not only enhances productivity but also reduces material waste. However, companies must constantly evaluate their machinery's performance. Misalignment or improper settings can lead to subpar results, defeating the purpose of this innovative technology. As the market continues to evolve, so too should our approach to utilizing these machines effectively.

Key Features of the 2026 Best Roll Lamination Machines

The 2026 roll lamination machines stand out with essential features that cater to various industries. A report from the Lamination Technology Association indicates that these machines offer enhanced productivity with speeds reaching up to 30 meters per minute. Such efficiency is crucial for businesses focusing on high-volume output. Moreover, these machines often integrate user-friendly touchscreens, enabling quick adjustments and reducing downtime.

Another key aspect is the versatility in lamination thickness. The best machines accommodate films ranging from 1.5 mil to 10 mil. This flexibility allows businesses to choose the perfect film for their specific needs. However, despite these advancements, users sometimes face challenges with film adherence. In certain conditions, improper alignment can lead to bubbles or wrinkles, impacting the finished quality. Industry studies suggest that while advancements exist, ongoing training is essential for operators to maximize machine capabilities.

Energy efficiency is also a noteworthy feature. Reports reveal that modern machines consume 30% less energy than their predecessors, contributing to sustainability goals. However, the initial investment may deter some smaller operations, making it vital to assess long-term costs. Understanding these features helps businesses choose the right equipment, ensuring they stay competitive in an evolving market.

Advantages of Using Roll Lamination Machines in Various Industries

Roll lamination machines have become essential in various industries for their unique advantages. These machines provide a protective layer to printed materials, enhancing durability. The lamination process also improves the appearance of documents, making them more appealing. This feature is particularly beneficial for businesses in marketing and education, where visual presentation matters.

The versatility of roll lamination machines stands out. They can handle a variety of substrates, from paper to plastics. This flexibility allows for custom solutions tailored to specific industry needs. However, the setup process can be tricky for operators unfamiliar with the equipment. Training is essential to maximize productivity. Not every run may yield perfect results, leading to waste and potential frustrations.

Another benefit is cost-effectiveness. While initial investments can be high, the long-term savings from reduced material damage are significant. Companies often find that laminated materials last longer, minimizing replacement costs. Still, achieving a balance between quality and efficiency can be a challenge. Not all products laminate evenly, which can be a point of concern. Industries must constantly evaluate and adapt their techniques to stay ahead.

Comparative Analysis of Different Roll Lamination Machines Available in 2026

In 2026, the market for roll lamination machines presents several options for users. Each machine offers unique features tailored to various applications. Some machines excel in speed, processing multiple layers quickly. Others focus on precision, ensuring high-quality finish even on intricate designs. Users often report challenges in finding machines that balance both speed and quality effectively.

Comparing models reveals key differences. Some machines are lightweight and portable, suitable for small operations. However, this portability can compromise stability, leading to inconsistent results during high-volume tasks. Conversely, heavier machines provide stability but may require more floor space. Maintenance is another crucial factor; some models have complex maintenance needs, deterring users from long-term investment.

Ultimately, assessing the features and benefits of each machine is vital. Potential buyers must consider their specific needs and workflow. Evaluating user experiences and real-world application outcomes can shed light on which machines truly perform as advertised. Balancing cost versus functionality remains a pressing issue, with some users wishing for better clarity on each machine's capabilities.

Maintenance Tips for Maximizing the Lifespan of Lamination Machines

When it comes to maintaining lamination machines, proactive care is crucial. Regular maintenance can extend the machine's lifespan significantly. Clean the rollers frequently to prevent adhesive buildup. This simple step avoids performance issues down the line. Ignoring this can lead to uneven lamination quality over time.

Next, always check the machine's settings before operation. Incorrect settings may cause unnecessary wear and tear. Ensure that the temperature and pressure are appropriate for the materials you are using. Mistakes happen, but taking a moment to double-check can save components from damage.

Lastly, develop a routine inspection schedule. Look for signs of wear, such as frayed belts or unusual noises. A quick inspection can catch problems early. If something feels off, don’t hesitate to pause and reassess. Operators can sometimes overlook these minor details, leading to bigger issues later. Simple awareness makes a significant difference.

Cost-Effectiveness and ROI of Investing in Roll Lamination Technology

Investing in roll lamination technology can be a game changer for many businesses. This technology offers enhanced durability and protection for printed materials. The cost-effectiveness is evident when you consider the minimal waste generated during the lamination process. With proper management, the need for reprints is greatly reduced.

However, the initial investment can be significant. It is important to assess whether the production volume justifies the cost. Smaller businesses might find it challenging to leverage the full benefits. Prioritizing projects where lamination would add significant value can help. Monitoring your ROI over time is crucial. You may notice improved customer satisfaction through the better quality of materials produced.

Roll lamination machines can also reduce labor costs. Automation speeds up the process, but it does require training. Employees need time to adjust. Mistakes in operation can lead to increased costs and waste. A balance must be struck between speed and quality to maximize the benefits of this technology.