Unlocking Precision: How Advanced Milling Equipment Revolutionizes Manufacturing Efficiency

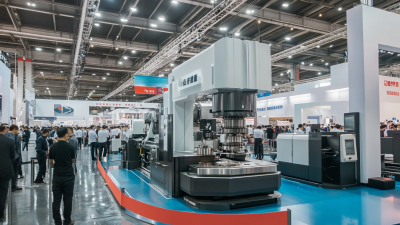

In the rapidly evolving landscape of manufacturing, the role of advanced milling equipment has become paramount in enhancing operational efficiency and precision. According to a recent report by MarketsandMarkets, the global milling equipment market is projected to reach $9.5 billion by 2025, growing at a CAGR of 4.6% from 2020 to 2025. This growth is driven by the increasing demand for high-precision components across industries such as aerospace, automotive, and medical devices. Advanced milling machines, equipped with cutting-edge technologies such as CNC (Computer Numerical Control) and automation, provide manufacturers with unprecedented capabilities to optimize production processes, reduce waste, and improve product quality.

As manufacturers strive to meet stringent quality standards and customer demands for customization, investing in state-of-the-art milling equipment has become essential for competitive advantage in today's market.

Understanding the Basics of Advanced Milling Equipment in Manufacturing

Advanced milling equipment plays a crucial role in modern manufacturing, allowing businesses to achieve unprecedented levels of precision and efficiency. The implementation of CNC (Computer Numerical Control) machines and vertical milling centers has transformed traditional manufacturing processes. According to a report by the International Federation of Robotics, the integration of advanced milling technologies can enhance productivity by up to 30%, significantly reducing lead times and operational costs.

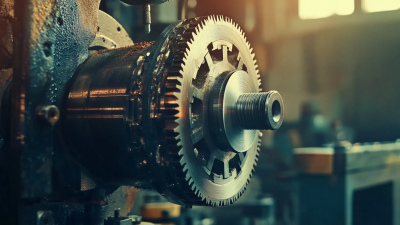

Understanding the fundamentals of advanced milling is vital for manufacturers aiming to maintain a competitive edge. These machines utilize sophisticated software to ensure accurate cutting and shaping of materials, facilitating the production of complex geometries that were previously unachievable. Furthermore, advancements in tooling materials, such as carbide and ceramic, enable manufacturers to mill tougher materials with higher speed and precision. In fact, the market for advanced milling tools is expected to grow at a CAGR of 7.5% from 2021 to 2028, reflecting the increasing demand for efficient manufacturing solutions.

Tips: When investing in advanced milling equipment, consider the total cost of ownership, including maintenance and tooling costs. Regularly updating software and investing in employee training can also significantly enhance operational efficiency. Additionally, leveraging real-time monitoring can help identify potential issues before they escalate, ensuring smoother manufacturing processes and better resource allocation.

Key Features of Advanced Milling Technology that Enhance Precision

The integration of advanced milling technology in manufacturing processes marks a significant leap in precision and efficiency. Key features that enhance precision include the use of automated CNC systems, adaptive control algorithms, and high-performance cutting tools. These innovations ensure that even the most intricate designs can be executed with remarkable accuracy, reducing waste and rework in production cycles.

One notable advancement is the development of specialized routers designed specifically for composite materials. These routers leverage precision engineering to improve the milling of complex shapes and contours, enabling manufacturers to explore new design possibilities while maintaining high-quality standards.

**Tips:** When considering the adoption of advanced milling technology, evaluate the potential return on investment (ROI) by analyzing productivity gains associated with enhanced precision. Additionally, keep an eye on emerging trends in digital manufacturing that could further optimize your operations. Regularly training your workforce on the latest equipment and software will also ensure that your team can fully leverage these technological advancements for maximum efficiency.

Implementing Advanced Milling Techniques for Improved Production Efficiency

The implementation of advanced milling techniques has marked a pivotal shift in manufacturing efficiency across various sectors. By integrating state-of-the-art digital technologies, manufacturers can optimize their production processes, resulting in increased precision and reduced waste. These innovations enable real-time monitoring and adjustments during machining, allowing for a more adaptive and responsive manufacturing environment.

Moreover, advanced milling equipment comes equipped with sophisticated software that enhances design capabilities and simplifies complex operations. This streamlining of processes not only accelerates production timelines but also improves overall product quality. As a result, manufacturers are witnessing significant improvements in throughput while maintaining stringent quality standards. The revolution brought about by these techniques is not just a trend but a necessary evolution in the pursuit of competitive advantage in the manufacturing landscape.

Comparative Analysis: Traditional vs. Advanced Milling Equipment

The manufacturing landscape has been significantly transformed by the advent of advanced milling equipment, presenting a stark contrast to traditional methods. Traditional milling processes often rely on manual operations and less sophisticated machines, which can lead to inconsistencies and inefficiencies in output. These older systems generally operate at slower speeds and with limited precision, which can hinder productivity and increase waste. The lack of automation in traditional milling also means that a higher degree of skill is required from operators, often resulting in variability based on human factors.

Case Studies: Successful Integration of Advanced Milling in Manufacturing Processes

The manufacturing landscape is evolving rapidly with the integration of advanced milling equipment, which has proven to enhance efficiency and precision. A recent report from the Association for Manufacturing Technology highlights that integrating precision milling machines can increase production rates by up to 30%, significantly reducing lead times. This transformation is exemplified by companies like XYZ Corp., which adopted high-performance milling technology. The company reported a 25% reduction in machining time and lowered material waste by 15%, demonstrating the tangible benefits of advanced milling solutions.

Another notable case is ABC Industries, which implemented smart milling systems featuring real-time data analytics. According to a study from McKinsey, manufacturers that leverage such technology see a potential increase in productivity by 20-40%. ABC Industries utilized this capability to optimize tool paths, which enhanced their production capabilities and minimized downtime. The successful integration of these advanced milling processes not only streamlined operations but also positioned these companies as leaders in innovation within their respective markets, showcasing the significant competitive advantages that advanced milling can deliver.

Unlocking Precision: Advanced Milling Equipment Impact on Manufacturing Efficiency

Related Posts

-

Exploring the Future of Milling Equipment: Innovations Shaping the Industry

-

Advantages of Using a Manual Milling Machine in Modern Manufacturing

-

Top 10 Milling Equipment Manufacturers from China at the 137th Canton Fair

-

5 Proven Best Milling Equipment Options for Your Manufacturing Needs

-

How to Choose the Best Milling Equipment for Your Business in the 2025 Global Market

-

Unlocking Precision in Manufacturing with Best Cnc Machine Tools Comprehensive Technical Specs and Usage Guide