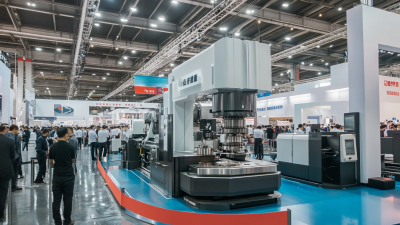

Solutions for Advanced Milling Machine Tools in Global Supply Chain Optimization

In today's competitive landscape, the optimization of global supply chains is crucial for manufacturers, particularly in the context of Milling Machine Tools. According to a report by the International Federation of Robotics, the demand for advanced milling technologies has increased by 15% over the past year, reflecting the industry's shift towards more automated and efficient production methods. This rising demand underscores the importance of integrating sophisticated milling machine tools within supply chain management strategies to enhance productivity and reduce lead times. Moreover, a study from McKinsey suggests that companies can achieve a significant reduction in operational costs—up to 20%—by embracing innovative milling solutions and aligning them with their supply chain processes. As we explore various examples in this blog, it will become evident how leveraging advanced milling machine tools not only improves manufacturing capabilities but also fosters greater agility and responsiveness in an increasingly complex global marketplace.

Challenges in Maintaining Precision in Advanced Milling Operations

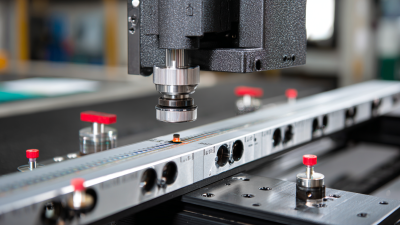

In the realm of advanced milling operations, maintaining precision is a multifaceted challenge that demands constant attention. According to a recent report from the International Manufacturing Technology Show, precision in machining can decline by nearly 20% due to inadequate calibration and wear over time. This deterioration not only affects production quality but can also lead to significant financial losses, with manufacturers potentially facing rework costs that exceed 5% of their total operational budget.

To tackle these challenges, incorporating regular maintenance schedules and implementing real-time monitoring systems is critical. Tip: Consider investing in automated diagnostic tools that can detect irregularities in milling performance before they escalate into larger issues. This proactive approach not only enhances operational efficiency but also boosts the overall quality of the output.

Impact of Supply Chain Disruptions on Milling Tool Availability

The supply chain disruptions caused by global events have had a significant impact on the availability of milling tools. According to a recent industry report, 73% of manufacturers have experienced delays due to supply chain crises, affecting production timelines and operational efficiency.

As milling machines are vital for precision manufacturing across various sectors, including aerospace and automotive, the unavailability of essential milling tools can hinder the entire production process.

Moreover, with the advent of advanced milling techniques, the demand for specialized tools has surged. A study noted that the global market for milling tools is projected to grow at a CAGR of 5.1% over the next five years, underlining the growing need for reliable supply chains.

In light of these disruptions, companies are urged to diversify their suppliers and invest in local manufacturing solutions to mitigate risks. By adopting advanced supply chain strategies and enhancing collaboration among stakeholders, the milling industry can better navigate these challenges and ensure the availability of critical tools in the face of future disruptions.

Strategies for Enhancing Supplier Collaboration in Milling Tool Procurement

In today’s competitive landscape, enhancing supplier collaboration in milling tool procurement is vital for optimizing the global supply chain. According to a report by Allied Market Research, the global milling tools market is projected to reach $5.9 billion by 2026, emphasizing the need for effective partnerships between manufacturers and suppliers. By fostering communication and trust, companies can streamline their procurement processes, reduce lead times, and ultimately improve production efficiency.

Tips: Establish regular check-ins and open lines of communication with suppliers. This not only helps to address issues promptly but also builds a collaborative environment. Additionally, leveraging data analytics can aid in identifying the best-performing suppliers, ensuring that resources are effectively allocated to those who optimize supply chain performance.

Another strategy to enhance supplier collaboration is to implement shared technology platforms. A joint platform enables real-time tracking of inventory levels, order statuses, and production schedules, reducing the risk of delays. According to a survey by Deloitte, 73% of high-performing supply chains utilize advanced technologies to maintain supplier relationships, showcasing the link between technology and collaboration.

Tips: Consider investing in cloud-based solutions that allow for transparency and immediate access to critical supply chain data. This fosters accountability and allows both parties to anticipate challenges before they escalate. Building a shared vision for success can lead to innovative solutions and a more resilient supply chain.

Supplier Collaboration Strategies for Milling Tool Procurement

Leveraging Technology for Real-Time Monitoring in Milling Supply Chains

In the rapidly evolving manufacturing landscape, real-time monitoring technology is transforming the efficiency of milling supply chains. By integrating sensors and IoT devices into advanced milling machine tools, manufacturers can collect data continuously, which provides insights into machine performance and production processes. This proactive approach allows businesses to

identify bottlenecks and reduce downtime, ultimately enhancing overall productivity.

Moreover, leveraging digital dashboards and analytics software enables stakeholders to visualize this data effectively. Real-time monitoring facilitates more informed decision-making by ensuring that teams can respond swiftly to any disruptions in the supply chain. For example, if a machine notices wear and tear,

maintenance alerts can be triggered automatically, preventing costly production halts. With these technologies, milling operations become more responsive and agile, aligning perfectly with global supply chain optimization goals. This not only enhances operational efficiency but also fosters a culture of

continuous improvement within the organization.

Evaluating the Cost-Benefit Ratio of Advanced Milling Solutions in Global Markets

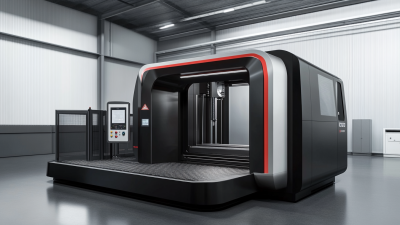

As global supply chains continue to evolve, the evaluation of advanced milling machine tools is pivotal for enhancing competitiveness. The cost-benefit ratio of these advanced solutions must be assessed meticulously to understand their value in various markets. According to a report by CIMdata, companies that implement advanced machining technologies can achieve reductions in operational costs by up to 25%, alongside a 30% increase in production efficiency. These improvements directly contribute to a more robust supply chain, allowing manufacturers to respond swiftly to market demands.

Moreover, a study conducted by the International Federation of Robotics indicates that investments in advanced milling technologies lead to a significant ROI over time. Specifically, firms adopting automation within their milling processes have reported a decrease in scrap rates by 40% and an increase in precision that enhances product quality. These data illustrate that while the initial investment in advanced milling solutions may seem substantial, the long-term savings and efficiency gains can substantially outweigh these costs, making a compelling case for their integration into global supply chains.

Related Posts

-

Top 10 Milling Equipment Manufacturers from China at the 137th Canton Fair

-

5 Proven Best Milling Equipment Options for Your Manufacturing Needs

-

How to Choose the Best Milling Equipment for Your Business in the 2025 Global Market

-

7 Essential Tips for Choosing the Right Milling Machine Tools

-

Global Excellence in Manufacturing with Chinese Quality the Best Coordinate Measuring Machine

-

Unlocking Precision: The Future of CNC Machining Centers for Global Buyers