Alloy Powder Grader Tips for Optimal Performance and Selection?

The choice of an Alloy Powder Grader significantly impacts the efficiency of powder processing. Selecting the right grader is not straightforward. Many factors influence performance, and attention to detail is crucial.

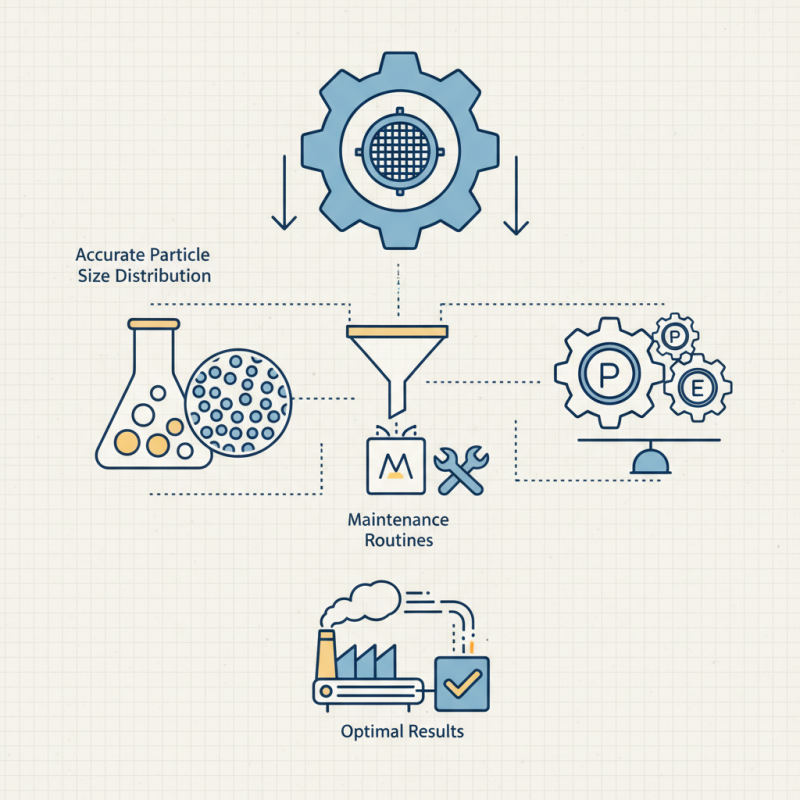

An ideal Alloy Powder Grader should provide accurate particle size distribution. Misjudgments in this selection can lead to waste and inconsistency. It’s important to evaluate options based on the specific alloy and application required.

Moreover, users often overlook maintenance routines. Regular checks can prevent performance degradation. Understanding the features of an Alloy Powder Grader is essential. Balancing precision with efficiency is key to achieving optimal results.

Understanding Alloy Powder Grading: Essential Concepts and Terminology

Alloy powder grading is crucial in various industries. Understanding the essential concepts and terminology helps in selecting the right alloy for specific applications. For instance, particle size distribution, density, and flow characteristics are key factors that influence performance. Grading systems categorize powders based on these attributes.

When choosing alloy powders, consider the intended application. Some alloys may perform better under high stress or extreme temperatures. Take time to analyze the specific requirements of your project. This analysis can save costly mistakes.

Tips for optimal performance include checking the purity of the alloy. Contaminants can drastically affect the final product. A careful selection process is vital. Also, keep in mind that storage conditions can impact powder quality. Always store in a controlled environment to prevent degradation. Reflect on these factors for better outcomes.

Alloy Powder Grader Performance Analysis

Factors Influencing Alloy Powder Selection for Specific Applications

When selecting alloy powders for specific applications, several key factors come into play. Material properties like hardness and ductility are crucial. For instance, data from the International Journal of Advanced Manufacturing Technology indicates that the thermal conductivity of alloy powder can significantly impact performance in heat treatment processes. Choosing the right powder ensures optimal results.

Tips for selection should include evaluating the mechanical properties, such as yield strength and elongation. A study by the American Society for Testing and Materials found that powders with higher purity levels tend to yield better mechanical performance. Test your powders for consistency. Variability can lead to unexpected failures in applications.

Another consideration is the particle size distribution. A report by Metal Powder Report highlights that finer powders often improve sintering characteristics. However, they may also increase the risk of agglomeration. Balance is key; aim for powder that meets your application’s needs while maintaining quality. Understanding these nuances can elevate your production outcomes significantly.

Alloy Powder Grader Tips for Optimal Performance and Selection

| Application | Alloy Type | Particle Size (µm) | Purity (%) | Key Properties |

|---|---|---|---|---|

| Aerospace Components | Aluminum Alloy | 20-50 | 99.7 | Lightweight, high strength |

| Automotive Industry | Magnesium Alloy | 30-70 | 99.5 | Corrosion resistance, good machinability |

| Medical Devices | Titanium Alloy | 10-25 | 99.9 | Biocompatible, durable |

| Construction | Copper Alloy | 50-100 | 99.0 | Good conductivity, high strength |

| Electronics | Nickel Alloy | 5-15 | 99.9 | Excellent corrosion resistance, electrical conductivity |

Techniques for Grading Alloy Powder for Optimal Performance

Grading alloy powder requires precision and attention to detail. The right grading technique can significantly affect performance. Various factors influence the quality of alloy powders, including size distribution and morphology. Accurate grading can enhance the material's properties, leading to improved mechanical performance.

Tips for grading alloy powders include using a suitable sieve analysis. This method helps determine particle size distribution effectively. Ensure the sieves used are calibrated and clean. Contamination can skew results. Another method is laser diffraction, which provides quick and precise sizing but may not capture all characteristics accurately.

When selecting an alloy powder, consider its application. Different industries require specific properties from their materials. A powder suitable for aerospace might not meet the needs of automotive applications. It's essential to review the characteristics required for your project. Testing small samples before full-scale use may prevent costly mistakes. Reflection on past selections can guide better decisions in the future.

Common Challenges in Alloy Powder Grading and Their Solutions

Grading alloy powders poses unique challenges. One significant issue is particle size distribution (PSD). An uneven PSD can impact the performance of the final product. According to industry reports, a consistent PSD enhances flowability by up to 25%. This consistency is crucial for processes like selective laser melting and powder metallurgy.

Another common challenge is contamination during grading. Alloy powders can absorb moisture and foreign particles, compromising integrity. Studies indicate that even a 1% contamination level can lead to significant performance decline in critical applications. Implementing rigorous washing processes and using closed systems for handling can help mitigate this risk.

Operators often face difficulties in accurately assessing quality during grading. Traditional methods may lack precision. Emerging technology, such as laser diffraction and automated image analysis, is changing this landscape. These methods improve measurement accuracy, reducing human error and ensuring product reliability. However, they require investment and training, which can be a barrier for some facilities. Reflecting on these challenges encourages a focus on continual improvement and innovation in the grading process.

Best Practices for Storing and Handling Alloy Powders for Longevity

Alloy powders can degrade quickly if not stored or handled properly. Proper storage conditions are crucial for maintaining the quality of alloy powders. A recent industry report highlights that improper storage can decrease the lifespan of powders by up to 30%. The ideal storage environment should be cool, dry, and dark to prevent oxidation and contamination.

When handling alloy powders, it’s essential to minimize exposure to air and moisture. Use sealed containers to protect them from environmental factors. Quick tip: Always wear gloves while handling powders. This prevents moisture from skin contact, ensuring the powders remain uncontaminated.

Regularly inspect storage containers for signs of issues. Even minor leaks can lead to significant quality loss. A proactive approach includes scheduling inspections to maintain optimal conditions. Remember, once contaminated, the powders may require disposal, leading to waste that can be avoided with diligent practices. Use these simple strategies to enhance the longevity and effectiveness of your alloy powders.