How to Choose the Right Damper Actuator for Your Needs?

Choosing the right Damper Actuator can seem challenging. There are many options available. Each type has unique features and specifications. Understanding your specific needs is crucial.

Consider the environment where the actuator will operate. Extreme temperatures or humidity can affect performance. Look at the required torque and speed. These factors often dictate the most suitable actuator.

Don’t forget about installation and maintenance. Some Damper Actuators require more care than others. Think about the long-term implications. Is the actuator easy to access? Reflect on your choices carefully. The right decision will enhance efficiency and reliability.

Understanding Damper Actuator Types and Their Applications

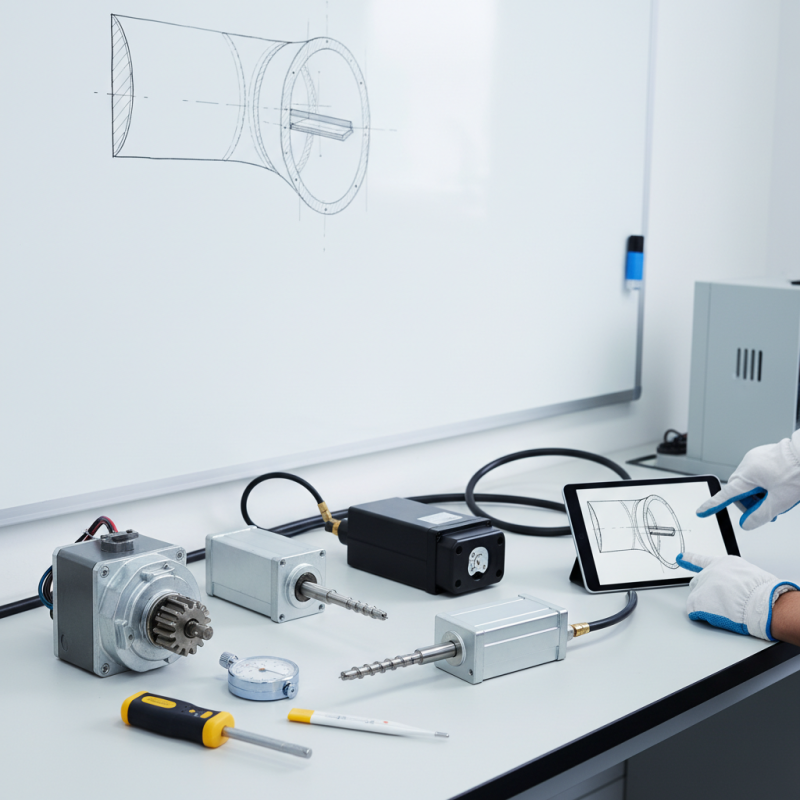

When selecting a damper actuator, it's vital to understand the types available. There are several common types, each suited for different environments and applications. Electric actuators are popular in indoor settings. They offer precise control and are easy to integrate with existing systems. Pneumatic actuators excel in industrial environments, handling high pressures efficiently. They are often used in large buildings.

Applications vary widely. For example, in HVAC systems, actuators control airflow effectively. In contrast, some processes require actuators that respond rapidly to changing conditions. That can be challenging, and one must think critically about the environment and specific tasks.

Selecting a damper actuator can be overwhelming. Technical specifications, placement, and power requirements all play vital roles. Take time to analyze your specific needs. A wrong choice can lead to inefficiencies. User feedback is often essential to understanding real-world performance. Don't hesitate to ask for insights from peers or professionals.

Assessing Key Specifications for Damper Actuator Selection

When selecting a damper actuator, the key specifications matter greatly. Start with torque requirements. Typically, an actuator needs about 10 to 50 Nm of torque for standard dampers. But, heavy-duty applications may require torque ratings up to 300 Nm. This variation is critical. Misjudging torque can lead to system failure or inefficiency.

Another essential specification is response time. Industry standards suggest an ideal response time of under 5 seconds. However, many actuators often exceed this range. Slow response times can disrupt system performance. Precision is crucial in HVAC systems, where climate control hinges on rapid adjustments.

Compatibility is equally important. Ensure the actuator integrates seamlessly with your existing control systems. Some actuators may not align with popular protocols. This oversight can cause delays and extra costs. Industry surveys indicate that about 30% of system failures stem from poor compatibility choices. It’s a sobering reminder of the challenges in actuator selection. Evaluate each requirement carefully to avoid future complications.

Evaluating the Control Mechanisms of Damper Actuators

When choosing a damper actuator, understanding the control mechanisms is vital. Different control types lead to varying responses in system performance. Typically, there are two main categories: on/off controls and modulating controls. On/off control is simpler, handling binary states. In contrast, modulating controls provide a continuous range of position adjustments. This precision is crucial for energy efficiency in HVAC systems.

A recent industry report indicates that modulating actuators can improve energy savings by up to 25% in large systems. This data highlights the importance of selecting the right actuator based on specific needs. Factors such as speed, torque, and feedback types also play a role in determining the ideal actuator. For instance, a slow response can lead to comfort issues in air distribution. Achieving the perfect balance in performance often requires trial and error.

Considerations like maintenance needs are also important. Some actuators require regular calibration, adding to long-term operational costs. Furthermore, the installation environment can significantly impact actuator performance. Constant exposure to extreme temperatures or humidity may degrade certain types. It’s essential to assess these conditions before making a choice. The right actuator must align with both functional requirements and operational conditions to ensure reliability and efficiency.

Determining Environmental Considerations for Actuator Usage

When selecting a damper actuator, understanding the environment where it will be used is crucial. Environmental factors significantly impact the actuator's performance and longevity. For instance, temperature extremes can reduce the effectiveness of an actuator. A report from the International Society of Automation suggests that most actuators operate optimally between 0°C and 50°C. Outside this range, their reliability decreases sharply.

Humidity is another key consideration. High humidity can lead to corrosion, especially in metal parts. The same report indicates that actuators exposed to humidity levels greater than 75% should have protective features. Additionally, dust and particulates can hinder movement. In industrial settings, dust levels often exceed recommended limits. A clean environment can enhance actuator durability and responsiveness.

Lastly, vibration levels must be taken into account. In locations subject to high vibrations, actuators might fail prematurely. Data from the American National Standards Institute highlights that consistent exposure to vibrations above 2g can reduce the lifespan of a standard actuator. Understanding these factors can mitigate future problems. Engineers should approach actuator selection with a clear understanding of their environmental demands to avoid costly mistakes.

How to Choose the Right Damper Actuator for Your Needs? - Determining Environmental Considerations for Actuator Usage

| Actuator Type | Torque Rating (Nm) | Operating Temperature (°C) | IP Rating | Power Supply (V) |

|---|---|---|---|---|

| Electric Actuator | 10 | -20 to 60 | IP65 | 24 |

| Pneumatic Actuator | 15 | -10 to 80 | IP54 | Compressed Air |

| Hydraulic Actuator | 25 | -40 to 70 | IP68 | Hydraulic Fluid |

| Mechanical Actuator | 5 | -20 to 50 | None | N/A |

Budgeting and Cost Factors in Damper Actuator Selection

When selecting a damper actuator, budget plays a crucial role. It's essential to assess upfront costs versus long-term savings. Some actuators may seem affordable at first but require costly maintenance. Look closely at the specifications and features of the devices you consider. Sometimes, the cheapest option does not deliver the best performance.

Factor in installation expenses, as improper setup can lead to failures. A quality actuator might save you money on repairs down the line. Evaluate energy efficiency as well. A more efficient model may cost more initially, but it can lower energy bills. You might find yourself spending less over the years.

Don't overlook warranty and support. A strong warranty reduces future financial risks. However, not all manufacturers offer the same level of service. Researching user reviews can reveal important insights into reliability. Reflect on your actual needs, and weigh them against your budget constraints. This balance is essential for making the right choice.