Crafted Precision Global Reach of Best Cnc Machine Tools from China

In the fast-evolving landscape of manufacturing, CNC machine tools have become indispensable for precision engineering across diverse industries. According to a report by MarketsandMarkets, the global CNC machine tools market is expected to grow from USD 80.8 billion in 2020 to USD 97.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.0%. This growth is largely driven by the increasing demand for automation and the need for high-quality manufacturing processes. As businesses seek to optimize productivity and maintain competitive edges, finding reliable suppliers of high-quality CNC machine tools is vital. In this ultimate guide, we will explore effective strategies for identifying top-tier suppliers from China, a leading hub for CNC machine tools, ensuring that manufacturers can leverage precision and innovation while meeting global market demands.

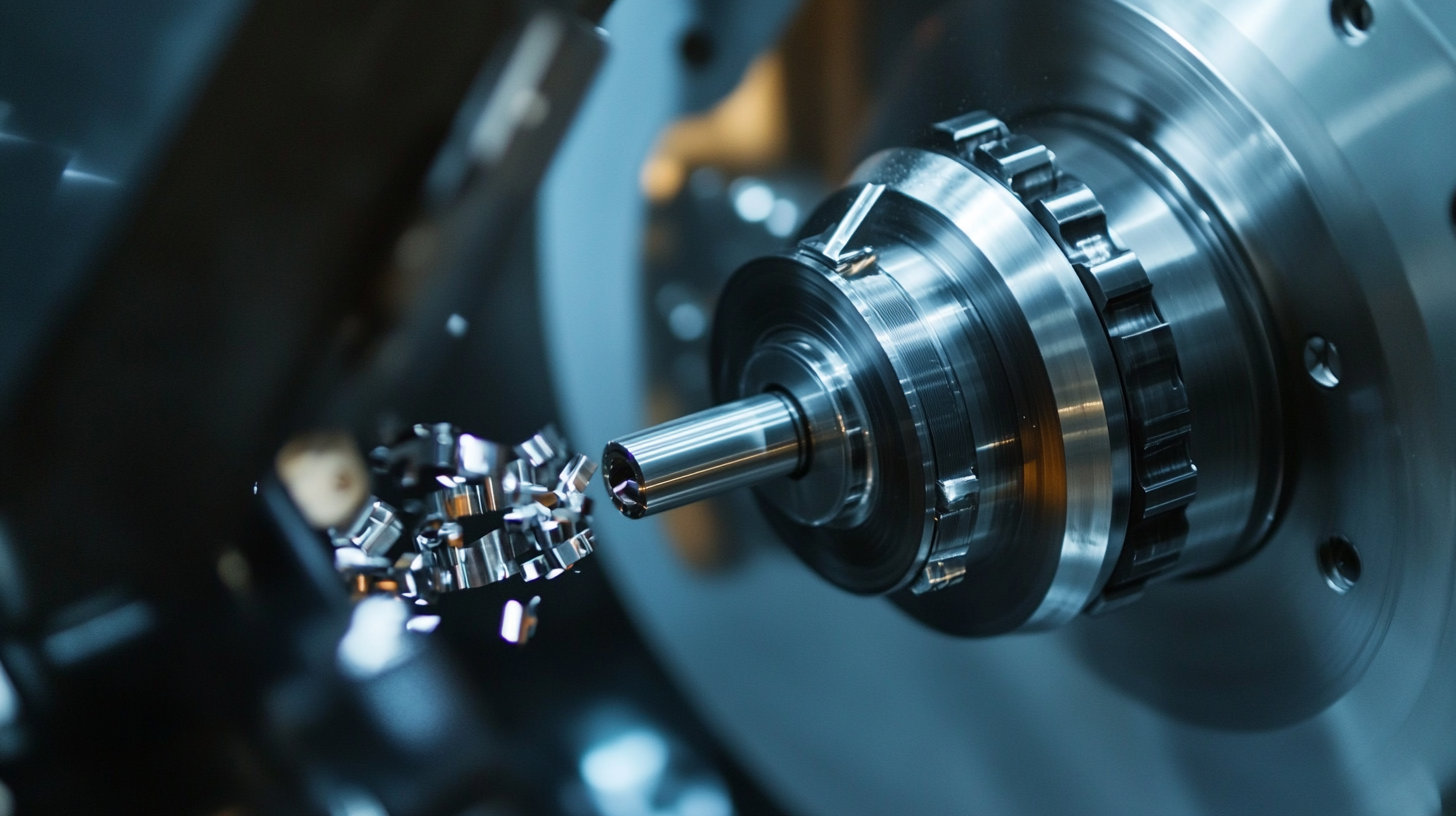

The Legacy of Precision Engineering in Chinese CNC Machine Tools

The legacy of precision engineering in Chinese CNC machine tools is not just a story of growth, but a testament to the country’s relentless pursuit of innovation and quality. Over the years, China has emerged as a global leader in CNC technology, leveraging its rich engineering heritage and vast resources. With a sharp focus on crafting precision tools, Chinese manufacturers have successfully enhanced their capabilities, producing machines that meet the highest standards of accuracy and efficiency.

As the global CNC machine market is set to grow significantly, reaching an estimated $195.59 billion by 2032, Chinese CNC machine tools are playing an increasingly important role. The advancements in end milling machines exemplify this trend, reflecting cutting-edge technologies that cater to precision metalworking needs. In cities like Zaozhuang, where technological growth is fueled by abundant natural resources, the CNC industry is seeing rapid development, pushing the limits of what's possible in precision engineering.

China’s dominance in machinery exports, particularly in the CNC sector, signifies not only the trust placed in its manufacturing capabilities by countries like the USA, Japan, and India, but also the impressive evolution of its engineering practices. As a result, Chinese CNC machine tools are becoming synonymous with precision and reliability on the global stage.

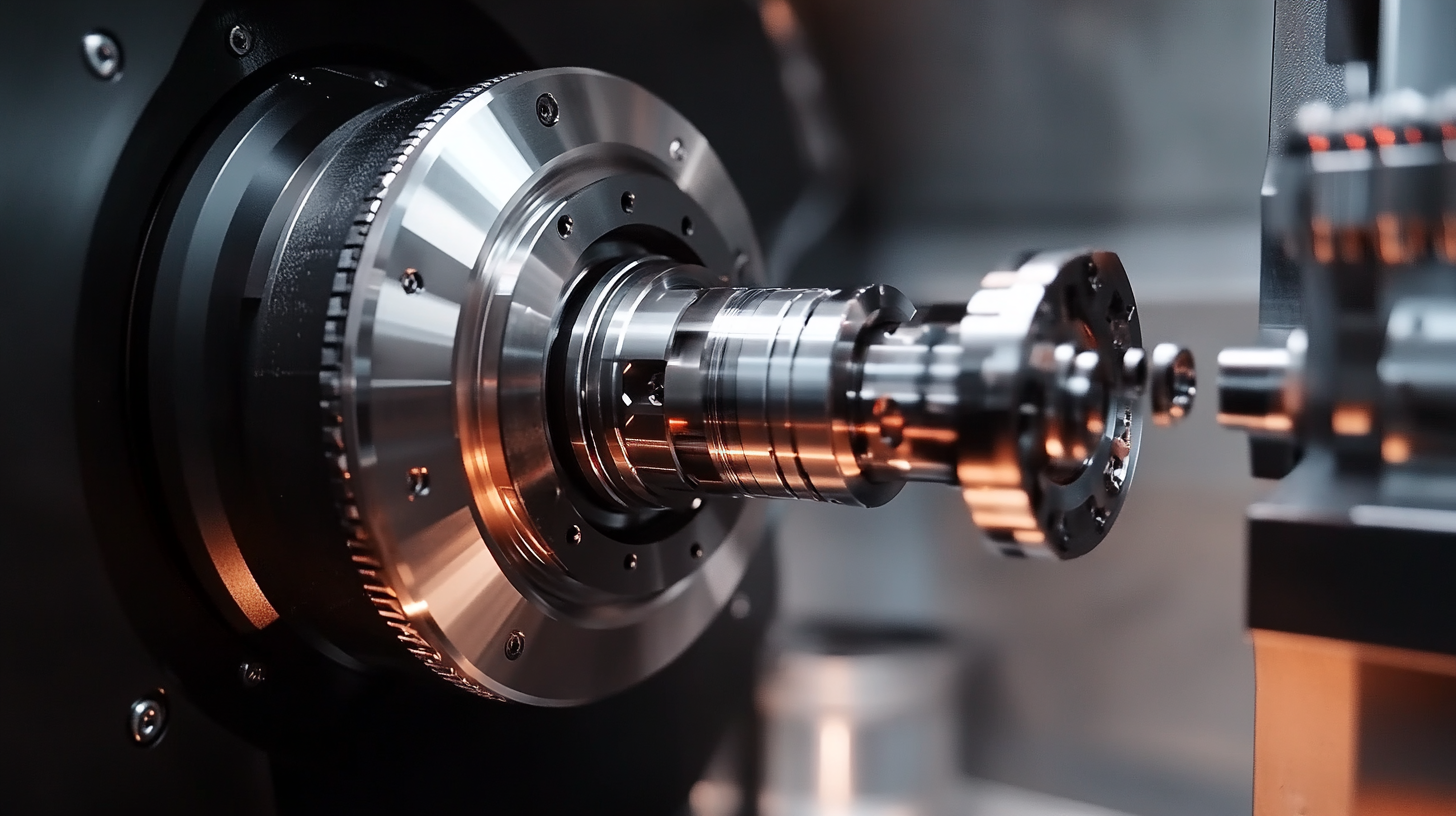

Unveiling the Advanced Technology Behind China’s CNC Manufacturing

The CNC machining industry is witnessing remarkable advancements, with China's manufacturing sector at the forefront of this evolution. The global market for CNC machines is predicted to escalate from $101.2 billion in 2025 to an impressive $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This surge is primarily driven by heightened demand in key industries such as automotive and aerospace, where precision and efficiency are paramount.

Recent initiatives by the Chinese government, including substantial funding measures to support equipment upgrades and the promotion of smart manufacturing, are setting the stage for a transformation in industrial capabilities. The integration of advanced technologies such as artificial intelligence and IoT is further enhancing the efficacy of CNC tools, enabling manufacturers to cater to more complex and diverse market needs. As highlighted in industry reports, China's commitment to high-end manufacturing is paving the way for a robust ecosystem that optimizes production processes and enhances global competitiveness, marking a pivotal shift in the industrial landscape.

Crafted Precision Global Reach of Best CNC Machine Tools from China

| Machine Type | Max Working Area (mm) | Spindle Speed (RPM) | Control System | Precision (mm) |

|---|---|---|---|---|

| Vertical Machining Center | 1500 x 800 x 600 | 10000 | Fanuc | 0.01 |

| CNC Lathe | 1000 x 300 | 5000 | Siemens | 0.005 |

| CNC Router | 2400 x 1200 x 200 | 24000 | Mach3 | 0.02 |

| EDM Machine | 600 x 400 x 300 | 2500 | Fanuc | 0.001 |

Quality Assurance Practices That Guarantee Top-notch CNC Machinery

When it comes to CNC machinery, ensuring quality is paramount. The rise of CNC machining in various sectors, particularly aerospace, has led manufacturers to adopt rigorous quality assurance practices. Effective quality assurance not only enhances the reliability of products but also builds trust among clients. Emphasizing precision, many manufacturers focus on personalized service to tailor CNC machining parts for specific needs. For instance, crafting individual aluminum components for equipment assembly can significantly boost operational efficiency.

Tips for maintaining top-notch quality in CNC operations include implementing regular inspections at different production stages. This practice allows for real-time adjustments and reduces the risk of defects. Additionally, investing in advanced calibration tools ensures that machinery operates within specified tolerances, which is critical in industries where precision is non-negotiable. Both new and established players in the market must prioritize these practices to compete effectively on a global scale.

Global Impact: How Chinese CNC Tools Are Reshaping Industries Worldwide

The global impact of Chinese CNC tools is significant as they play a crucial role in reshaping industries worldwide. China's machine tool industry stands as the largest globally, with a remarkable market value exceeding RMB 200 billion (around USD 27.86 billion). This rapid expansion is not just a number; it reflects a growing trend towards advanced manufacturing and automation, with China positioning itself as a leader in innovation and technology.

According to recent projections, the global machine tools market is expected to surge from USD 82.9 billion in 2022 to approximately USD 139.69 billion by 2032, illustrating a compound annual growth rate (CAGR) of over 7.0%. This growth signifies a robust demand for more precise, efficient, and technologically advanced CNC tools, and China is at the forefront of this trend. By harnessing its capabilities and competitive advantages in manufacturing, Chinese companies are set to dominate the global market, ensuring that industries worldwide evolve and adapt to new manufacturing paradigms influenced by cutting-edge CNC technology.

Global Impact of Chinese CNC Machine Tools

This chart illustrates the global market share of CNC machine tools from China over the past five years, showcasing their increasing influence across various industries. The data reflects the growing adoption of advanced machining technologies provided by Chinese manufacturers.

Customer Success Stories: Transforming Operations with Chinese CNC Solutions

As the global manufacturing landscape evolves, customer success stories highlight the transformative impact of Chinese CNC (Computer Numerical Control) solutions. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, driven largely by the adoption of advanced technologies and automation in manufacturing processes. Companies that have integrated Chinese CNC machine tools have reported significant increases in operational efficiency and a marked reduction in production costs.

One notable case includes a leading automotive component manufacturer that adopted a range of CNC solutions sourced from China. By implementing these precision tools, they achieved a 30% improvement in their machining accuracy and a 25% decrease in lead times. Furthermore, a prominent aerospace firm experienced enhanced scalability and productivity, resulting in a 40% boost in output. These stories exemplify how businesses are leveraging the innovative capabilities and competitive pricing of Chinese CNC technology to enhance their operational frameworks, making it a preferred choice in the quest for manufacturing excellence.