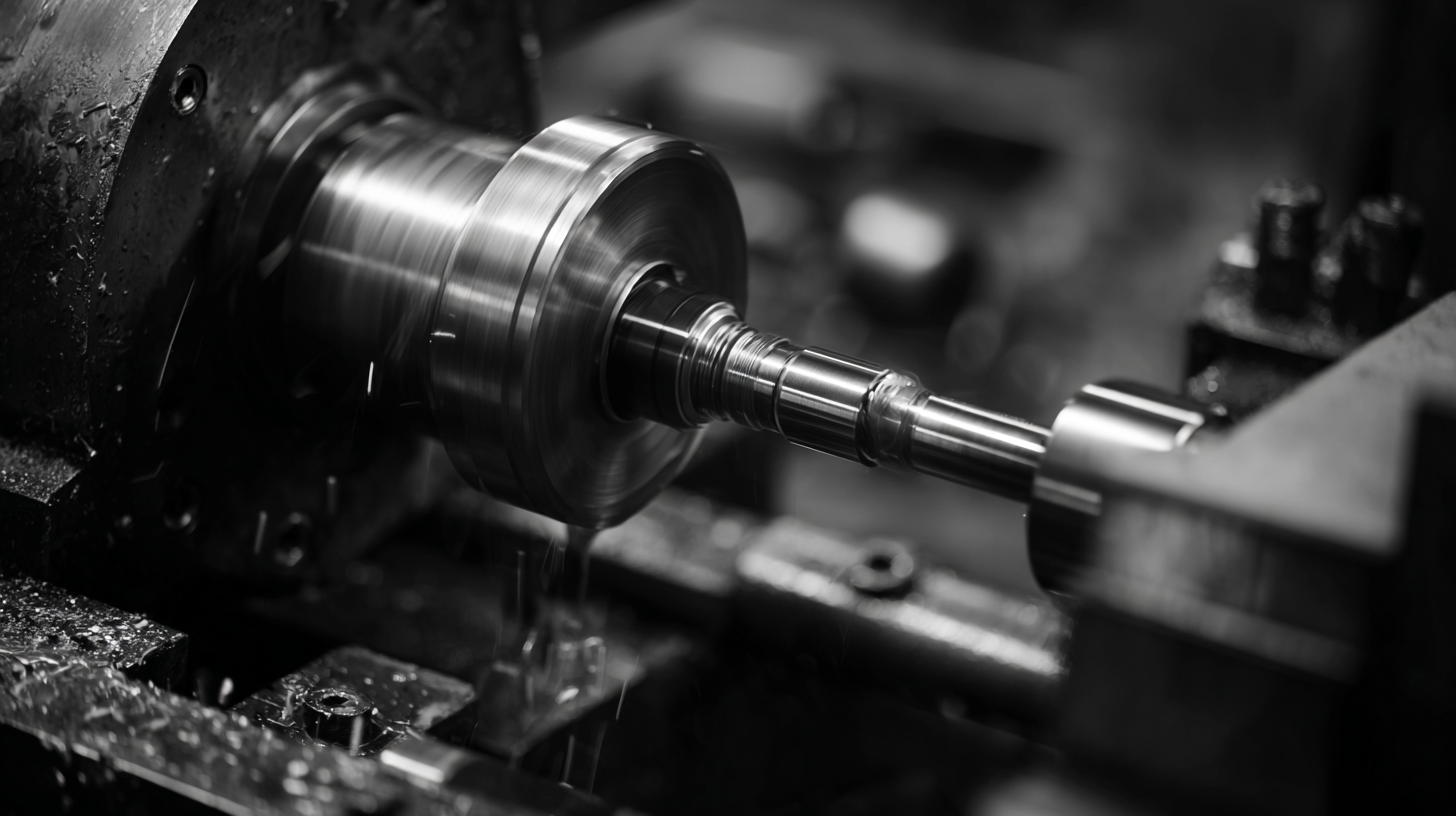

10 Essential Lathe Machine Tools You Need for Maximum Efficiency

In the world of manufacturing, the efficiency and precision of metalworking operations heavily rely on the selection of appropriate Lathe Machine Tools. According to a report by Grand View Research, the global lathe machine market size was valued at over $3 billion in 2021, with a projected compound annual growth rate (CAGR) of 5.2% from 2022 to 2030. This significant investment underscores the necessity for manufacturers to equip themselves with essential tools that optimize performance while minimizing downtime. Integrating the right Lathe Machine Tools not only enhances productivity but also ensures high-quality output, which is critical in competitive industries such as aerospace and automotive. As technology continues to evolve, knowing which tools are indispensable will enable operators to achieve maximum efficiency and maintain a competitive edge in the market.

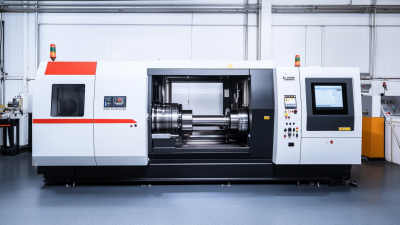

Choosing the Right Lathe Machine for Your Workshop Needs

When selecting the right lathe machine for your workshop, several critical factors come into play. According to the Industrial Manufacturing Report 2023, over 45% of manufacturers reported increased productivity by investing in modern lathes tailored to their specific needs. The ideal lathe should match the scale of your operations, whether you're working on large-scale production or precision manufacturing for intricate parts. Understanding different lathe types, such as CNC lathes or manual lathes, can significantly influence your output efficiency.

Tips: Consider your workshop's space and power requirements before purchasing. A compact CNC lathe can save space and offer high precision, while a larger, more robust lathe will cater to bulkier projects.

Another vital aspect is the tooling and accessories that accompany your lathe machine. A report from the Machinery Buyers Council highlighted that manufacturers who utilize multi-functional tooling systems can boost their machining efficiency by up to 30%. Choosing the right accessories such as tool holders, chucks, and part catchers can optimize your lathe's performance and enhance production capability.

Tips: Regularly assess and upgrade your tooling inventory to avoid downtime and maintain productivity. Investing in high-quality cutting tools can lead to longer life and better finishing.

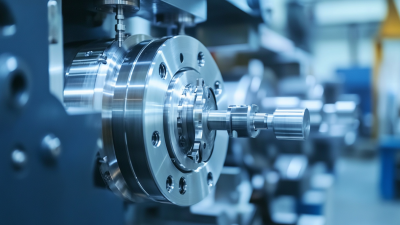

Key Accessories to Enhance Lathe Machine Performance

In today's rapidly evolving manufacturing landscape, enhancing lathe machine performance is crucial for maximizing efficiency. Key accessories, such as advanced tool holders, optimized cutting tools, and automated tool changers, significantly contribute to operational effectiveness. With the global CNC machine market projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, an impressive CAGR of 9.9% indicates a pressing need for manufacturers to adopt these essential tools for improved productivity.

Moreover, the infusion of intelligent systems into India's machine tool industry underscores the shift towards reliability and scalability. By integrating cutting-edge technologies, manufacturers can optimize lathe machine operations, resulting in enhanced flexibility and performance. This strategic adoption of smart operations, which elevate traditional manufacturing concepts, is pivotal as the CNC machines market is also expected to reach approximately $170.4 billion by 2033, growing at a CAGR of 9.80%. Such growth highlights the importance of investing in key accessories that not only boost lathe machine capabilities but also drive overall industry advancements.

Essential Cutting Tools for Precision Machining

When it comes to precision machining, the right cutting tools are vital for achieving maximum efficiency. According to the *Global Cutting Tools Market Report 2022*, the demand for cutting tools is projected to grow at a CAGR of 6.2% over the next five years. This growth underscores the importance of investing in high-quality lathe machine tools to meet increasing production demands while maintaining accuracy and maximizing tool life.

Essential cutting tools, such as carbide inserts, end mills, and boring bars, are foundational to effective lathe operations. For instance, carbide inserts are known for their durability and ability to endure high cutting speeds, reducing downtime and increasing productivity. The *Machinery & Equipment Manufacturing Insights* report indicates that utilizing superior cutting tools can enhance machining efficiency by up to 30%. Moreover, advanced tooling solutions, like multi-tasking tools giving the flexibility to perform multiple operations, can significantly minimize setup times, further bolstering production agility in competitive manufacturing environments.

Investing in these essential tools not only improves precision but also catalyzes overall operational efficiency.

Safety Equipment Every Lathe Operator Should Have

When operating a lathe machine, safety should always be the top priority. Every lathe operator must be equipped with essential safety gear to minimize the risks associated with machining operations. Firstly, wearing safety goggles is crucial. They provide essential eye protection against flying debris and shavings that can cause serious injuries. Additionally, a face shield can offer an extra layer of protection when working with larger materials or when performing operations that produce excessive splinters.

Another vital piece of safety equipment is ear protection. The loud noise generated by lathe machines can lead to hearing damage over time. Using earmuffs or earplugs helps safeguard an operator’s hearing, enabling them to work comfortably and efficiently. In addition to personal protective equipment, it is important for operators to wear non-loose-fitting clothing and sturdy, closed-toe footwear. This reduces the risk of fabric getting caught in moving parts, as well as providing protection for the feet against heavy materials and equipment. Overall, ensuring proper safety gear is in place allows lathe operators to focus on their tasks while minimizing the chances of accidents.

10 Essential Lathe Machine Tools You Need for Maximum Efficiency - Safety Equipment Every Lathe Operator Should Have

| Tool Name | Function | Material | Safety Equipment | Comment |

|---|---|---|---|---|

| Lathe Chuck | Holds the workpiece in place | Steel | Safety Goggles | Essential for securing workpieces |

| Cutting Tool | Processes material by cutting | High-Speed Steel | Ear Protection | Various shapes available for different tasks |

| Tailstock | Supports the end of long workpieces | Cast Iron | Face Shield | Critical for stability |

| Carriage | Moves the cutting tool | Aluminum | Protective Gloves | Allows for precise movements |

| Tool Holder | Secures the cutting tool | Steel | Apron | Prevents tool movement |

| Belt Drive System | Transmits power | Rubber | Steel-Toed Boots | Important for torque delivery |

| Lubrication System | Reduces friction | Oil | Dust Mask | Essential for machine longevity |

| Digital Readout | Displays precise measurements | Plastic | Safety Curtains | Improves accuracy |

| Measuring Instruments | Ensure dimensional accuracy | Various materials | Emergency Stop Button | Critical for quality control |

Maintenance Tools to Extend the Life of Your Lathe Machine

Maintaining your lathe machine is crucial for achieving maximum efficiency and extending its operational life. Regular maintenance tools and practices can significantly enhance the performance of your lathe, ultimately leading to improved productivity in your operations. For instance, the global carbide tools market is projected to grow significantly, reflecting the increasing reliance on high-quality tools for effective maintenance and machining. By investing in top-tier maintenance tools, you can ensure your lathe operates at peak performance, minimizing downtime and operational costs.

**Tips:** It's essential to run regular diagnostic checks to assess the condition of your lathe and perform preventive maintenance whenever necessary. Implementing an IoT-based data-driven predictive maintenance strategy can help anticipate potential failures before they occur. Moreover, engaging in thorough cleaning and lubrication routines will safeguard against wear and tear, allowing your lathe machine to serve you effectively for many years.

As industries progress, the need for innovative solutions, such as green machine tools that reduce waste and energy consumption, becomes increasingly important. Embracing these advancements can lead to more sustainable manufacturing processes while also enhancing the lifespan of your lathe. By prioritizing maintenance and investing wisely in your tools, you can optimize the performance of your production line and cater to the evolving demands of the market.

10 Essential Lathe Machine Tools for Maximum Efficiency

This bar chart displays the importance rating of essential lathe machine tools for achieving maximum efficiency in operations. A higher rating indicates that the tool is crucial for maintaining performance and longevity of the lathe machine.

Related Posts

-

Exploring Options: What to Consider When Choosing Your Next CNC Tool Room Lathe

-

Future Trends in Global Market for Best Lathe Machine by 2025

-

Exploring the Advantages of Integrating Lathe and Milling Machine in Modern Manufacturing

-

Ultimate Guide to Finding the Best Used Machine Tools for Your Business Needs

-

Maximizing Value with Quality Used Machine Tools Through Cost Effective Maintenance Solutions

-

5 Proven Best Milling Equipment Options for Your Manufacturing Needs