7 Essential Tips for Choosing the Right Milling Machine Tools

Choosing the right milling machine tools is a critical decision for manufacturers and hobbyists alike, as it directly impacts precision, efficiency, and the overall quality of the final product. With numerous options available in the market, selecting the appropriate tools can be overwhelming.

This blog will present seven essential tips to help guide you through this important process. From understanding the specific needs of your projects to evaluating tool materials and compatibility, we will explore key factors that can influence your choice.

By emphasizing these considerations, you will be better equipped to make informed decisions that enhance your milling operations, ultimately leading to improved productivity and cost-effectiveness.

Whether you are a seasoned machinist or a newcomer to the world of milling, these insights will serve as valuable guidelines in your quest for the perfect milling machine tools.

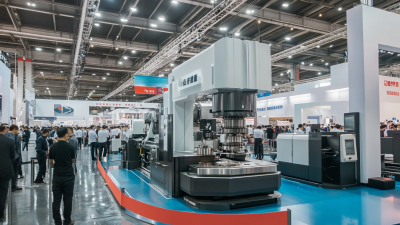

Understanding the Different Types of Milling Machines and Their Applications

When selecting a milling machine, it is crucial to understand the different types available and their specific applications. Milling machines generally fall into two main categories: vertical and horizontal. Vertical mills are ideal for tasks that require precision, like drilling and cutting complex shapes, while horizontal mills excel in operations involving larger workpieces and multiple cuts. Each type has its distinct features—such as spindle orientation, table movement, and tooling options—that cater to diverse manufacturing needs.

Furthermore, the choice of milling machine significantly impacts the overall efficiency and quality of production. For instance, CNC (Computer Numerical Control) milling machines provide advanced automation, allowing for intricate designs and high-volume production with minimal operator intervention. On the other hand, manual mills offer more hands-on control and can be beneficial for simpler projects or educational purposes. Understanding these nuances not only aids in selecting the right machine but also enhances the final output, minimizing issues like burr formation during the milling process.

Key Factors to Consider When Selecting Milling Machine Tools for Your Business

When selecting milling machine tools for your business, it's crucial to consider several key factors that can significantly impact your operations and bottom line. First, assess the specific needs of your production processes. Different types of milling machines serve various functions, from basic shaping to complex CNC machining tasks. Understanding the material types, volume, and precision required in your production will help determine the optimal machine types and features necessary for your operations.

Market trends also indicate substantial growth in the CNC machine sector, projected to increase from $101.22 billion in 2025 to $195.59 billion by 2032. This rapid expansion highlights the rising demand for advanced milling machines that can offer superior automation and efficiency. Features such as programmable control systems, ease of integration into existing workflows, and the ability to handle diverse material and application needs are essential to consider. Furthermore, evaluating the long-term maintenance and support plans from suppliers can ensure that your investment remains functional and beneficial over time.

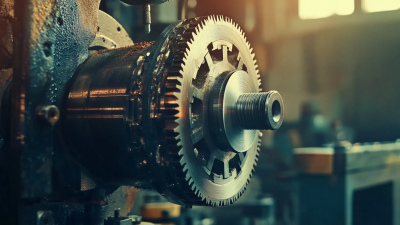

Analyzing Material Compatibility: Choosing the Right Cutting Tools for Milling

When selecting the right cutting tools for milling, analyzing material compatibility is crucial. Different materials demand specific tool types to ensure optimal performance and longevity. For instance, when machining aluminum alloys, tools with superior wear resistance, such as those made from high-speed steel or carbides, are often preferred. Recent studies highlight the importance of utilizing advanced cutting fluids, including tri-hybrid nanofluids, which can enhance lubrication and cooling properties during the cutting process, thereby improving efficiency and tool life.

Another key consideration is the tool geometry and coating, which should align with the material being machined. For instance, using deep cryogenically treated tools can significantly increase durability when turning steels like AISI 1045. Additionally, specialized coatings can aid in reducing friction and wear, making them suitable for high-speed operations, especially with tough materials such as NiTi shape memory alloys. Understanding these dynamics empowers machinists to make informed decisions, maximizing productivity while minimizing costs.

Cost vs. Quality: How to Make Informed Decisions in Milling Tool Investments

When investing in milling machine tools, the balance between cost and quality is crucial. While it may be tempting to opt for the cheaper options available on the market, these tools can sometimes compromise performance and longevity. Poor-quality tools may lead to increased downtime, frequent replacements, and, ultimately, higher costs in the long run. Therefore, it is essential to analyze the total cost of ownership, which includes not only the purchase price but also maintenance, performance efficiency, and the impact on the overall machining process.

Informed decision-making begins with understanding your specific machining needs and production volume. High-quality milling tools that come with a higher price tag can enhance productivity and precision, promising better results over time. Consider factors like material compatibility, cutting speeds, and tool life when comparing options. Investing in reputable brands known for their durability and performance can lead to substantial savings and improved workflow, making the initial investment worthwhile. Always assess the long-term benefits before making a final decision; this approach will steer you toward tools that meet both your budget and quality requirements.

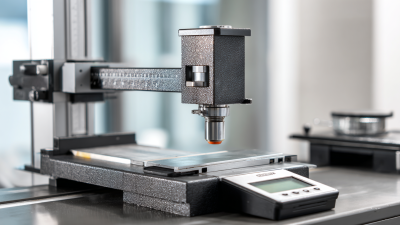

Trends in Milling Technology: What Modern Advancements Mean for Tool Selection

In recent years, advancements in milling technology have revolutionized the way we select and use milling machine tools. The integration of smart machinery and automation has enhanced precision and efficiency, making it crucial for operators and manufacturers to stay informed about these trends. With innovations such as CNC (Computer Numerical Control) systems, milling machines can perform complex tasks with minimal human intervention, allowing for more intricate designs and tighter tolerances. This shift demands that tool selection aligns closely with the capabilities of modern machines.

Moreover, the development of advanced materials and coatings for milling tools has transformed performance standards. Tools made from high-speed steel (HSS), carbide, and even ceramic composites offer improved durability and cutting efficiency, suitable for various applications. Additionally, coatings like TiAlN (Titanium Aluminum Nitride) not only increase tool life but also reduce friction, resulting in smoother operations. As these technologies continue to evolve, understanding their role in tool selection becomes essential, ensuring that operators choose solutions that maximize productivity and maintain competitive advantages in the manufacturing landscape.

Related Posts

-

Top 10 Milling Equipment Manufacturers from China at the 137th Canton Fair

-

Advantages of Using a Manual Milling Machine in Modern Manufacturing

-

5 Proven Best Milling Equipment Options for Your Manufacturing Needs

-

Exploring Options: What to Consider When Choosing Your Next CNC Tool Room Lathe

-

Top Strategies for Selecting the Best Measuring Equipment for Your Business

-

Exploring Future Innovations in CNC Lathes for Global Manufacturers in 2025