Exploring the Future of Milling Equipment: Innovations Shaping the Industry

The milling equipment industry is on the brink of a transformative era, driven by a wave of innovative technologies and practices that promise to reshape the future of production and processing. As manufacturers seek ways to enhance efficiency, reduce costs, and minimize environmental impact, they are turning to cutting-edge solutions that integrate automation, advanced materials, and smart technologies. This exploration into the future of milling equipment is not only about improving traditional practices but also about adapting to the changing needs of various sectors, including agriculture, food production, and manufacturing. In this evolving landscape, understanding the implications of these innovations is crucial for stakeholders aiming to stay competitive. By examining the current trends and future prospects in milling equipment, we can gain valuable insights into how these advancements are poised to redefine the capabilities of the industry and foster sustainable growth.

The Rise of Automation in Milling Equipment: Enhancing Efficiency and Precision

The future of milling equipment is increasingly being shaped by advancements in automation, which enhances both efficiency and precision in machining processes. The global CNC machine market is anticipated to witness significant growth, with projections estimating it will soar from $101.22 billion in 2025 to $195.59 billion by 2032. This expansion is driven by the integration of smart technologies and automation in milling equipment, leading to improved performance and reduced operational costs.

One notable innovation is the development of high-precision vertical turning centers that offer integrated automation and IoT readiness. These machines enable simultaneous 4-axis machining, which greatly reduces production time while maintaining high quality. Additionally, AI-driven tool wear detection systems are becoming essential in precision milling environments. These systems help monitor tool conditions, thereby ensuring accuracy and enhancing surface finish, which ultimately leads to more cost-effective operations.

Tips: When considering automation in your milling operations, evaluate the specific needs of your production process. Look for equipment that offers flexible kinematics to adapt to various workflows. Moreover, investing in AI-driven technologies can significantly reduce downtime by proactively managing tool wear and optimizing performance.

Exploring the Future of Milling Equipment: Innovations Shaping the Industry

| Innovation | Description | Impact on Efficiency | Impact on Precision | Implementation Status |

|---|---|---|---|---|

| Automated Milling Systems | Integration of robotics for automatic material handling. | Increases throughput by up to 30%. | Maintains consistent quality with minimal variance. | Widely adopted. |

| Smart Sensors | Real-time monitoring of machine performance and conditions. | Reduces downtime by predictive maintenance. | Enables fine-tuning of operations for higher accuracy. | Partially implemented. |

| Artificial Intelligence | AI algorithms to optimize milling parameters in real-time. | Increases operation efficiency by up to 25%. | Enhances precision through adaptive learning. | Emerging technology. |

| Advanced Material Processes | New materials used in tools for improved cutting and durability. | Improves tool life and reduces replacement costs. | Allows for higher precision machining. | Fully integrated. |

| Cloud-Based Solutions | Remote monitoring and management of milling operations. | Facilitates real-time adjustments to enhance workflow. | Improves the quality of the final product via remote control. | In development. |

Smart Milling Technologies: Leveraging IoT for Real-Time Performance Monitoring

The milling equipment industry is on the brink of digital transformation, driven by the integration of smart technologies and the Internet of Things (IoT). Innovations in smart milling technologies have enabled real-time performance monitoring, enhancing operational efficiencies and reducing downtime. According to a report by MarketsandMarkets, the global smart manufacturing market, which includes smart milling solutions, is projected to reach $565 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.7%.

With IoT sensors and advanced analytics, manufacturing plants can now gather and analyze data continuously from their milling equipment. This capability allows for predictive maintenance, where potential issues can be detected and resolved before they lead to costly failures. A study by Grand View Research highlights that industries adopting IoT solutions in their operations saw a 20-30% increase in productivity. By leveraging real-time data, operators can optimize milling processes, minimize waste, and enhance overall product quality, paving the way for future advancements in the milling sector.

Sustainable Milling Practices: Innovations Reducing Waste and Energy Consumption

The milling industry is undergoing a transformative phase, emphasizing sustainability and efficiency. Innovations in milling equipment are focused on reducing waste and energy consumption. According to a 2022 report by the International Milling Association, energy-efficient milling machines can cut energy use by up to 30%. These advancements not only minimize operational costs for businesses but also align with global sustainability goals.

Tips for implementing sustainable practices include optimizing machine settings to match production needs, which reduces unnecessary energy use, and conducting regular maintenance to ensure machines run efficiently. Additionally, integrating advanced technologies such as IoT can help monitor energy consumption and waste production, leading to more informed decision-making.

Furthermore, the adoption of eco-friendly materials and processes is gaining traction in the milling industry. A study by the Food and Agriculture Organization indicates that adopting circular economy principles in milling can reduce waste by up to 40%. Companies are now investing in technologies that allow for the recycling of by-products, contributing to a more sustainable supply chain.

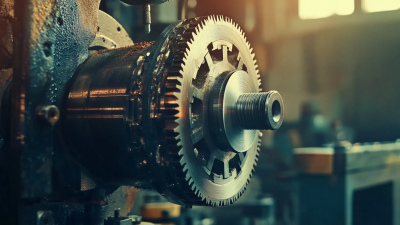

Advanced Materials in Milling Equipment: Improving Durability and Performance Standards

The milling equipment industry is currently witnessing a transformative phase, driven by innovations in advanced materials. These materials are not only enhancing the durability of milling equipment but are also setting new benchmarks for performance. High-performance alloys and composites are increasingly being integrated into the design of milling machinery, significantly reducing wear and tear while extending operational life. This shift is enabling manufacturers to produce equipment that can withstand the rigors of advanced milling processes while maintaining precision and efficiency.

Tips: When selecting milling equipment, consider the type of materials involved in its construction. Invest in options that incorporate advanced alloys, as they offer superior strength and longevity. Regular maintenance and inspections can also help prolong the life of your equipment, ensuring optimal performance over time.

Additionally, the development of smart materials is paving the way for even greater advancements. These smart materials can adapt to various operational conditions, improving efficiency and reducing energy consumption. As the industry moves forward, the integration of advanced materials will continue to play a pivotal role in refining milling techniques and enhancing overall productivity.

Tips: Stay informed about the latest trends in material science related to milling. Collaborate with suppliers who prioritize innovative materials in their product lines to ensure you are getting the best equipment for your operations.

Innovations in Milling Equipment: Impact of Advanced Materials

This chart illustrates the durability ratings of various advanced materials used in milling equipment. The ratings reflect how innovations in material science are influencing the performance standards and longevity of milling tools.

Trends in Milling Equipment Design: Adapting to Industry 4.0 Challenges and Opportunities

The milling equipment industry is undergoing a significant transformation driven by Industry 4.0, which emphasizes automation, data exchange, and real-time communication. As of 2023, market reports indicate that the global milling equipment sector is projected to grow at a CAGR of 5.2%, reaching an estimated value of $9.3 billion by 2027. This growth is largely fueled by advancements in technology that integrate artificial intelligence and IoT (Internet of Things) into milling processes, enhancing efficiency and reducing operational costs.

Innovations in milling equipment design are not only focusing on increased throughput but also on the sustainability of production methods. According to a recent study by MarketsandMarkets, over 45% of manufacturers are investing in energy-efficient machines that reduce waste and lower carbon footprints. Moreover, intelligent systems that analyze production data in real-time are enabling predictive maintenance, which can lead to downtime reductions of up to 25%. These trends reflect a broader shift in the industry towards smart manufacturing practices that enhance productivity while addressing environmental concerns.

Related Posts

-

Advantages of Using a Manual Milling Machine in Modern Manufacturing

-

Top 10 Milling Equipment Manufacturers from China at the 137th Canton Fair

-

5 Proven Best Milling Equipment Options for Your Manufacturing Needs

-

Unlocking Precision in Manufacturing with Best Cnc Machine Tools Comprehensive Technical Specs and Usage Guide

-

7 Essential Tips for Choosing the Right Milling Machine Tools

-

7 Reasons Why CNC Machining Centers Are Essential for Modern Manufacturing Success