Future Trends in Global Market for Best Lathe Machine by 2025

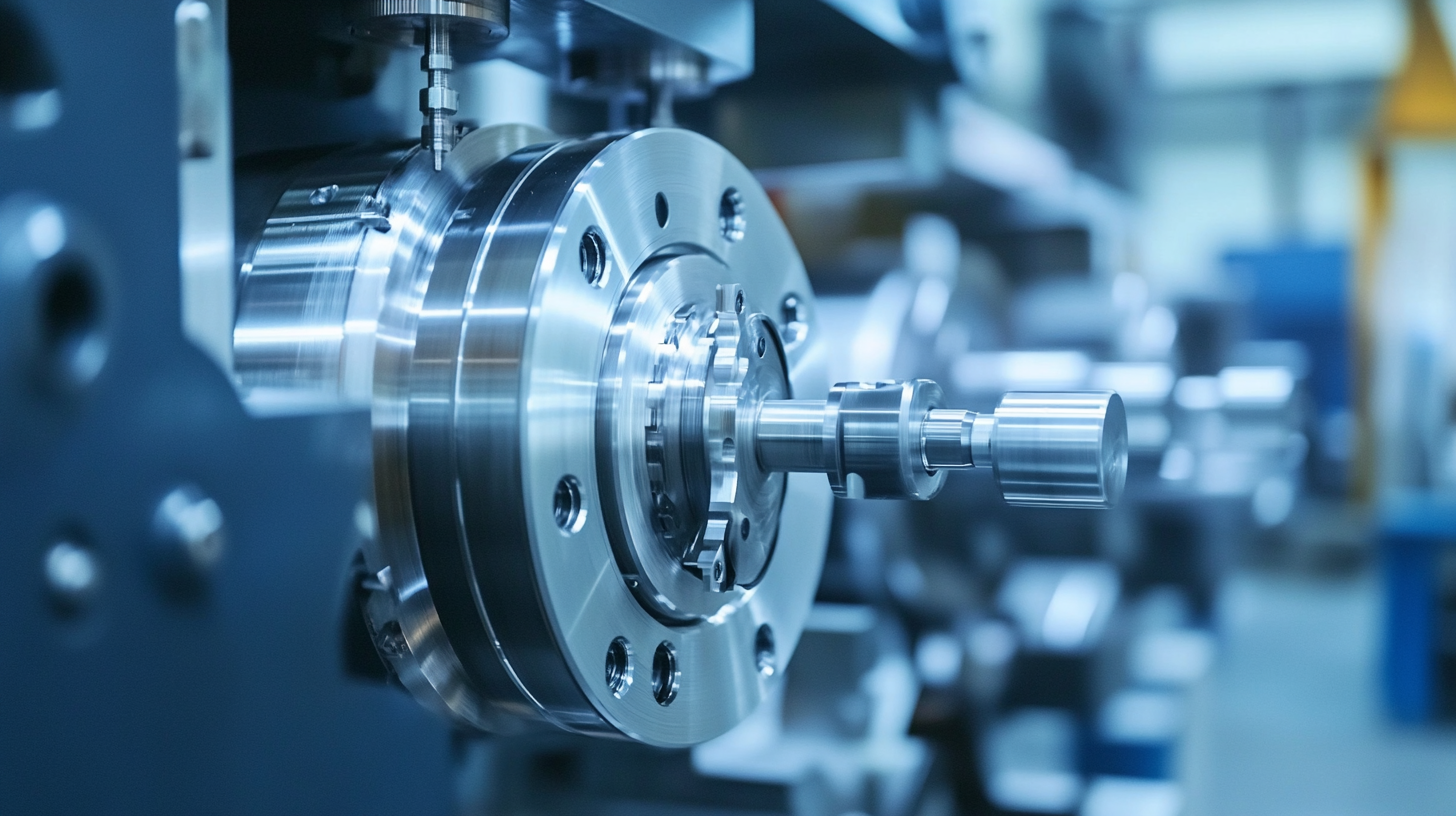

The global lathe machine market is poised for significant growth, projected to reach a value exceeding $5 billion by 2025, according to a recent report by Market Research Future. As industries increasingly seek precision and efficiency in their manufacturing processes, the demand for high-quality lathe machines continues to soar. This trend is further driven by advancements in technology, facilitating the creation of automated and CNC (Computer Numerical Control) lathes that enhance productivity and reduce human error. However, finding a reliable supplier of lathe machines is crucial for businesses aiming to leverage these advancements. In this blog, we will explore how to identify top-tier suppliers and secure the best lathe machines, ensuring that companies stay competitive in an ever-evolving market landscape.

The global lathe machine market is poised for significant growth, projected to reach a value exceeding $5 billion by 2025, according to a recent report by Market Research Future. As industries increasingly seek precision and efficiency in their manufacturing processes, the demand for high-quality lathe machines continues to soar. This trend is further driven by advancements in technology, facilitating the creation of automated and CNC (Computer Numerical Control) lathes that enhance productivity and reduce human error. However, finding a reliable supplier of lathe machines is crucial for businesses aiming to leverage these advancements. In this blog, we will explore how to identify top-tier suppliers and secure the best lathe machines, ensuring that companies stay competitive in an ever-evolving market landscape.

Emerging Technologies Shaping the Lathe Machine Market by 2025

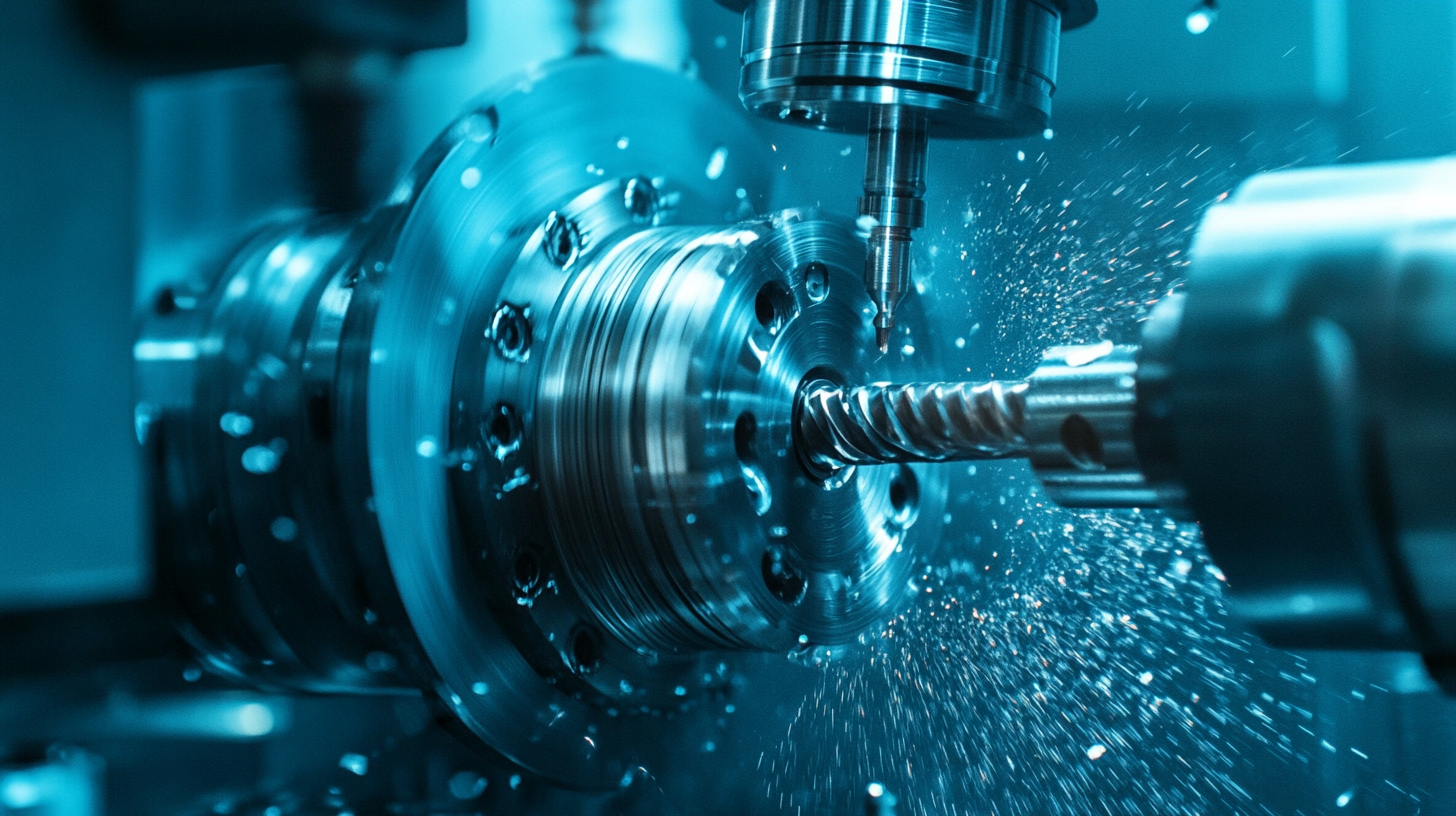

The lathe machine market is experiencing a transformative phase, driven by emerging technologies that are reshaping manufacturing processes. By 2025, we can expect to see advancements in automation and artificial intelligence that enhance precision and efficiency. Smart lathes equipped with IoT capabilities will allow for real-time monitoring and data analytics, enabling operators to anticipate maintenance needs and reduce downtime.

Another significant trend is the rise of sustainable manufacturing practices. With increasing environmental concerns, manufacturers are focusing on energy-efficient lathe machines that minimize waste while maximizing output. Innovations such as advanced material cutting techniques and eco-friendly lubricants are set to gain traction, appealing to both cost-conscious and environmentally aware businesses. The integration of these technologies not only streamlines production but also aligns with global efforts to promote sustainability in the manufacturing sector.

Projections for Lathe Machine Market Growth: A Data-Driven Analysis

The lathe machine market is on the brink of transformative growth, driven by advancements in automation and precision engineering. As industries continue to embrace technology, the demand for highly efficient and precise lathe machines is set to increase significantly. This trend aligns with the broader market dynamics, where the global machine tools market is projected to rise substantially from USD 134.96 billion in 2023 to USD 169.47 billion by 2028. Such growth is indicative of a shift toward enhanced production capabilities and better manufacturing efficiencies.

Moreover, the increasing integration of Computer Numerical Control (CNC) systems within lathe machines is reshaping market forecasts. With the CNC machine market size expected to reach USD 162.16 billion by 2032, driven by the surge in demand for precision and automation, it's clear that lathe manufacturers must pivot towards incorporating such technologies to remain competitive. As industries across the globe, including those in Asia-Pacific and Australia, invest heavily in modern machine tools, the future for lathe machines appears promising, ushering in a new era of manufacturing excellence.

The Role of Automation in Enhancing Lathe Machine Efficiency

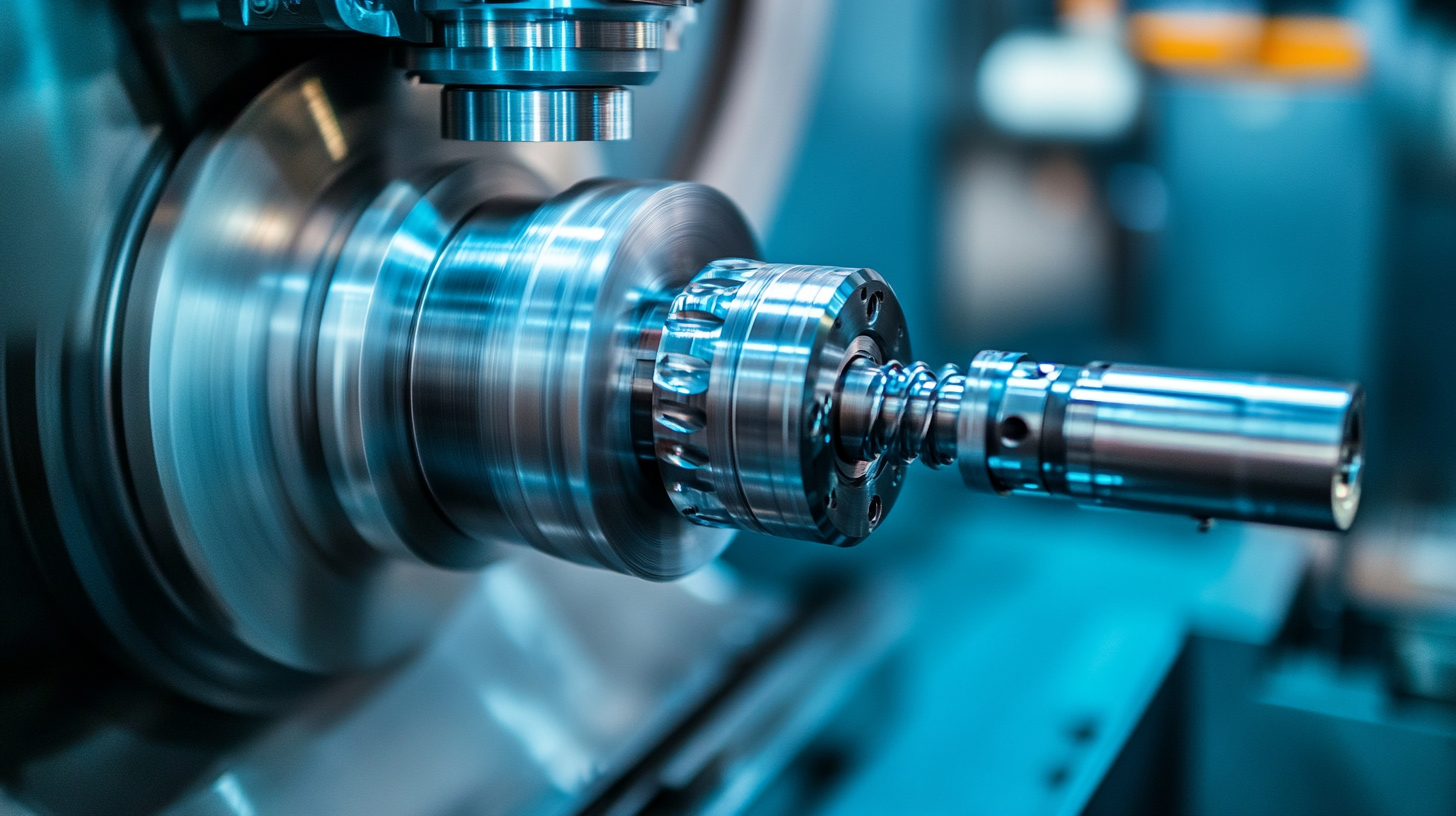

The landscape of lathe machines is rapidly evolving, driven by the advent of automation technologies. By 2025, we anticipate that automation will play a central role in enhancing the efficiency of lathe machines, fundamentally transforming manufacturing processes. Modern lathe machines are now equipped with sophisticated software that allows for real-time monitoring and control. This not only minimizes human error but also enables operators to optimize cutting speeds and improve the overall quality of the finished product.

Moreover, the integration of robotics and artificial intelligence into lathe operations will streamline workflows, allowing for faster production cycles. Automated systems can handle repetitive tasks, freeing skilled workers to focus on more complex operations and innovations. As manufacturers increasingly adopt these advanced technologies, they will experience significant cost savings and improved productivity, leading to a more competitive position in the global market. By embracing automation, companies can ensure they remain at the forefront of the industry, meeting the growing demands of precision engineering and customized manufacturing solutions.

Sustainability Trends Impacting Lathe Machines and Manufacturing

As the manufacturing sector progresses towards more sustainable practices, the lathe machine industry is witnessing significant transformations. Sustainability trends are reshaping how lathe machines are designed, produced, and utilized, pushing manufacturers to adopt eco-friendly materials and energy-efficient operations. Companies are increasingly focusing on minimizing waste through advanced technologies that optimize the machining process. For instance, innovations such as digital twins and real-time monitoring systems allow for better resource allocation, effectively reducing material scrap and enhancing overall efficiency.

Moreover, the integration of recyclable components into lathe machine production is becoming a standard practice. Manufacturers are now sourcing materials that can be easily repurposed, reducing the carbon footprint associated with raw material extraction and processing. Additionally, as global regulations tighten around emissions and waste management, lathe machine producers are compelled to innovate continuously. This proactive shift towards sustainable manufacturing not only meets regulatory requirements but also appeals to environmentally conscious consumers, ultimately shaping a more responsible and forward-thinking industry by 2025.

Key Players in the Lathe Machine Industry: Competitive Landscape Analysis

The lathe machine market is projected to experience significant growth in the coming years, with forecasts estimating a rise from USD 15.09 billion in 2024 to USD 19.27 billion by 2032. This expansion represents a compound annual growth rate (CAGR) of approximately 3.1%. The demand for lathe machines is being driven by an increasing need for precision manufacturing across various sectors, including automotive, aerospace, and metalworking.

Key players in the lathe machine industry are focusing on technology advancements, particularly in CNC (Computer Numerical Control) systems, which enhance automation and precision in machining processes. The market analysis indicates that the CNC machines segment is set to retain a significant share of the market, as businesses seek to optimize productivity and reduce manual labor costs. As the industry evolves, competition among manufacturers is expected to intensify, pushing innovations that meet evolving customer demands and sustainability standards.