Leading Global Manufacturer of The Best Lathe and Milling Machines for Export

In today's highly competitive manufacturing landscape, the significance of precision engineering cannot be overstated. At the forefront of this innovation are lathe and milling machines, essential tools that empower manufacturers to achieve unparalleled accuracy and efficiency in their production processes. This guide will explore the world of lathe and milling machines, highlighting the leading global manufacturers that are setting industry standards and driving advancements in technology. Whether you are a seasoned professional in the machining industry or a newcomer eager to delve into manufacturing, understanding the capabilities and advantages of these machines is crucial. From optimizing workflow to enhancing product quality, this blog aims to provide valuable insights into selecting the best lathe and milling machines for export, ensuring that you make informed decisions for your business or projects.

Leading Innovations in Lathe and Milling Machines: A Look at Industry 4.0 Integration

In the age of Industry 4.0, the integration of advanced technologies into manufacturing processes has revolutionized the production landscape, particularly in the field of lathe and milling machines. Leading global manufacturers are now harnessing the power of smart systems, IoT, and automation to enhance efficiency and precision in machining operations. These innovations not only optimize production workflows but also reduce downtime, ultimately paving the way for more sustainable manufacturing practices.

Moreover, the application of data analytics in lathe and milling operations allows for real-time monitoring and predictive maintenance, ensuring that machines operate at peak performance. Features such as remote diagnostics and machine learning algorithms enable manufacturers to anticipate potential issues before they arise, significantly limiting operational disruptions. As companies strive to remain competitive in a rapidly evolving market, embracing these cutting-edge technologies will serve as a fundamental strategy to drive growth and maintain a leading edge in the global marketplace.

Innovations in Lathe and Milling Machines: Industry 4.0 Integration

Global Market Trends: Statistics on Lathe and Milling Machine Demand and Supply

The global market for lathe and milling machines is witnessing a remarkable transformation, driven by growing industrial demands and advancements in technology. As per recent projections, the global lathe machine market was valued at approximately $25.4 billion in 2023 and is expected to expand to $35.84 billion by 2032. This growth trajectory highlights the increasing reliance on precision machinery in diverse sectors, including automotive, aerospace, and manufacturing.

One of the key factors fueling this expansion is the emphasis on high-precision machining centers that cater to the evolving needs of industries. The CNC machine tools market is projected to grow significantly, with an anticipated increase of around $21.9 billion between 2025 and 2029. Driven by innovations such as Artificial Intelligence, which enhances operational efficiencies and accuracy, manufacturers are now able to deliver more sophisticated solutions, pushing the boundaries of what is achievable in machining technology. As these trends continue, the demand for both lathe and milling machines is set to rise, reinforcing their essential role in modern manufacturing processes.

Leading Global Manufacturer of The Best Lathe and Milling Machines for Export - Global Market Trends

| Country | Lathe Machines Demand (Units) | Milling Machines Demand (Units) | Lathe Machines Supply (Units) | Milling Machines Supply (Units) | Year |

|---|---|---|---|---|---|

| USA | 25,000 | 30,000 | 24,000 | 28,000 | 2023 |

| Germany | 20,000 | 22,500 | 19,000 | 21,000 | 2023 |

| China | 50,000 | 60,000 | 48,000 | 55,000 | 2023 |

| India | 30,000 | 35,000 | 28,000 | 32,000 | 2023 |

| Japan | 15,000 | 18,000 | 14,000 | 16,000 | 2023 |

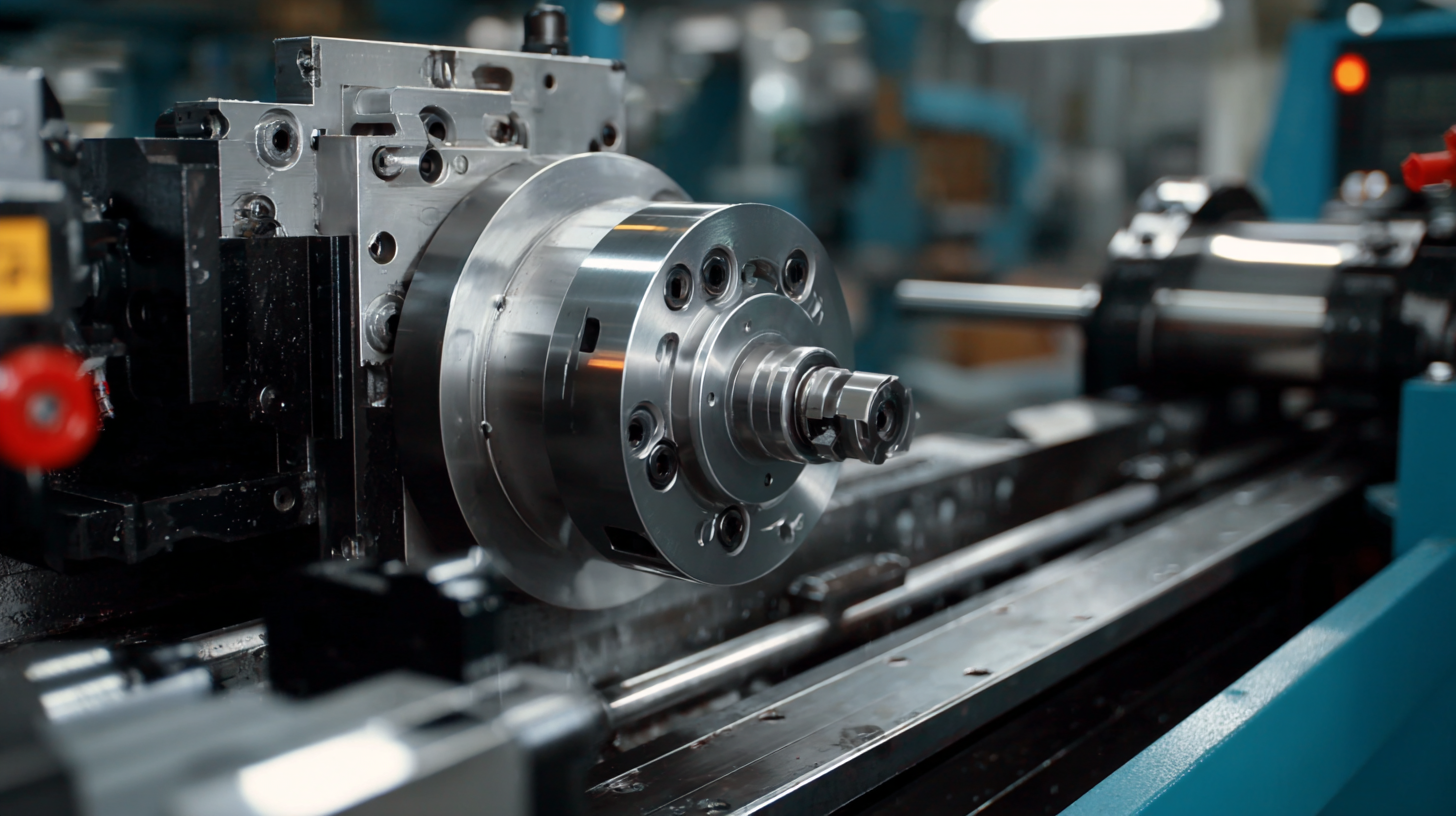

The Impact of Precision in Manufacturing: Key Metrics for Lathe and Milling Performance

In the realm of manufacturing, precision is paramount, especially when it comes to lathe and milling operations. These machines play a crucial role in shaping materials with high accuracy, which directly impacts product quality and operational efficiency. To gauge the performance of lathe and milling machines, several key metrics come into play, including dimensional accuracy, surface finish, and cycle time. Manufacturers must continuously monitor these metrics to ensure that their machines remain aligned with industry standards and customer expectations.

Dimensional accuracy refers to how closely a finished part's measurements align with the specified dimensions. This metric is vital for maintaining consistent quality in mass production. Surface finish, on the other hand, influences not only the aesthetic appeal of the product but also its functionality and durability. Lastly, cycle time— the time it takes to complete a machining operation— is critical as it directly affects productivity and profitability. By focusing on these key metrics, manufacturers can enhance the performance of lathe and milling machines, ensuring they remain competitive in the global market.

Sustainability in Manufacturing: How Top Exporters are Reducing Carbon Footprint

In the evolving landscape of manufacturing, sustainability has become a paramount concern, especially for top exporters. As industries face increasing pressure to mitigate their carbon footprint, initiatives in manufacturing are being enhanced through innovative practices. Recent studies indicate that carbon emissions from the manufacturing sector dominate global emissions, necessitating comprehensive strategies for reduction. A report on manufacturing servitization suggests that service-oriented approaches can effectively decrease embodied carbon emissions across 38 countries, highlighting a shift from traditional manufacturing practices towards more sustainable models.

To further promote sustainability, manufacturers can adopt advanced technologies that enhance efficiency. Innovations in sustainable building materials are gaining traction, with a focus on the lifecycle assessment of products, enabling businesses to understand better their environmental impact. For instance, a detailed life cycle assessment of coffee production between Brazil and Vietnam revealed significant insights into the carbon footprint associated with agricultural exports. This kind of analysis is crucial for manufacturers seeking to align their operations with global sustainability goals.

**Tips:**

- Implement energy-efficient technologies in manufacturing processes to lower operational emissions.

- Regularly assess the supply chain's carbon footprint to identify areas for improvement.

- Embrace service-oriented business models to shift towards sustainability and reduce waste.

Emerging Technologies: The Role of Automation in Modern Lathe and Milling Machines

The manufacturing sector is experiencing a transformative shift, with automation playing a pivotal role in enhancing the efficiency and precision of lathe and milling machines. As these machines move towards smart manufacturing, the integration of automation technologies is not just a trend but a necessity to remain competitive in the global market. Automated lathe and milling machines are equipped with advanced features that allow for real-time monitoring and adjustments, significantly reducing downtime and improving overall productivity.

Emerging technologies, such as AI and IoT, are at the forefront of this revolution. These innovations enable manufacturers to gather and analyze vast amounts of data, leading to smarter operational decisions. For instance, predictive maintenance powered by machine learning algorithms helps in anticipating issues before they disrupt production. This not only extends the lifespan of equipment but also ensures a higher quality of finished products, reinforcing the reputation of manufacturers as leaders in the export market.

In conclusion, embracing automation in lathe and milling machines not only streamlines production processes but also aligns with the evolving demands of customers worldwide. As the industry continues to innovate, those who leverage these technologies will undoubtedly set the pace for others to follow.