Mastering CNC Lathes A Comprehensive Guide to Precision Machining Techniques and Best Practices

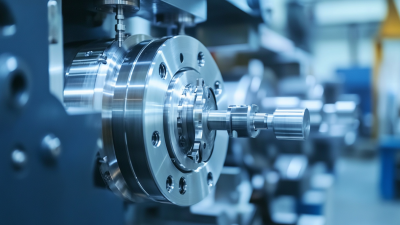

In the world of precision machining, mastering CNC lathes stands as a vital skill for both amateur and seasoned machinists alike. These powerful tools revolutionize the manufacturing process, enabling the creation of intricate components with unmatched accuracy and speed. This comprehensive guide aims to navigate you through the myriad techniques and best practices tied to CNC lathes, ensuring you harness their full potential. Whether you are looking to enhance your existing skills or are completely new to the field, understanding the nuances of CNC lathes is crucial.

From setup and tool selection to programming and troubleshooting, this guide will provide you with the foundational knowledge and practical insights needed to excel in CNC machining, ultimately leading to higher efficiency and quality in your projects. Join us as we delve deep into the world of CNC lathes, equipping you with the tools necessary to transform your machining endeavors.

Exploring CNC Lathe Alternatives for Various Machining Needs

When considering precision machining, CNC lathes are often the first tool that comes to mind. However, exploring CNC lathe alternatives can enhance versatility and efficiency in various machining applications. For instance, milling machines offer the ability to create complex shapes and surface finishes that a traditional lathe may struggle to achieve. They excel at tasks that require intricate detail and multi-dimensional workpieces, making them an invaluable option for projects that demand precision.

Another effective alternative is the use of laser cutters or water jets, particularly for materials that are difficult to machine with traditional methods. These technologies can cut through metals and composites with exceptional accuracy, allowing for intricate designs and reducing material waste. By integrating these alternatives into a machining workflow, manufacturers can optimize their processes and adapt to diverse machining needs, ensuring they are well-equipped to handle a variety of production requirements. This approach not only maximizes output but also fosters innovation in design and functionality.

Comparative Analysis of Traditional Lathes vs. CNC Lathes

The global machine tool market is anticipated to grow significantly, rising from $13.63 billion in 2025 to $22.946 billion by 2032, showcasing a compound annual growth rate (CAGR) of 8.1%. This burgeoning growth is influenced heavily by the advancements in precision machining technologies, particularly seen in the comparison between traditional lathes and CNC lathes. CNC lathes stand out with their ability to execute complex designs with high repeatability and precision, making them essential in modern manufacturing where accuracy is paramount.

In contrast, traditional lathes, while still valuable, offer limited automation and are generally less efficient for high-volume production. The evolution of CNC technology has redefined manufacturing processes, with CNC machines representing a significant leap in machining capabilities. Reports indicate that the lathe machinery market specifically will expand from $25.01 billion in 2018 to $57.54 billion by 2032, reflecting a CAGR of 5.6%. As industries evolve, the shift towards CNC lathes exemplifies the drive for higher productivity and adaptability in manufacturing environments, unlocking new opportunities across various sectors.

Innovative Technologies in Precision Machining Beyond CNC

The landscape of precision machining is evolving rapidly, thanks to innovative technologies that extend beyond traditional CNC lathes. According to the 2022 World Precision Machining Market report, advanced manufacturing technologies, including additive manufacturing and automation, are anticipated to propel market growth by over 10% annually through 2026. These innovations are not only enhancing production efficiency but also enabling higher precision levels that were previously unattainable. For instance, companies adopting integrated robotic systems are witnessing reductions in cycle time by up to 30%, underscoring the effectiveness of automation in machining processes.

In addition to automation, the rise of smart manufacturing techniques is transforming the industry. The implementation of the Internet of Things (IoT) in machining allows for real-time data collection and analysis, leading to proactive maintenance and reduced downtime. The 2023 Smart Manufacturing Technology Trends report indicates that businesses leveraging IoT technologies have enhanced their operational efficiency by approximately 20%, while also decreasing waste and improving product quality. As these innovative practices continue to gain traction, precision machining is entering a new era, characterized by enhanced adaptability and increased competitiveness in the global market.

Choosing the Right Lathe for Your Specific Machining Projects

When embarking on precision machining projects, selecting the right CNC lathe is crucial for achieving the desired results. Today's lathes are no longer the heavy, hulking machines of the past; they are now smart, compact, and versatile, capable of executing intricate designs with ease. According to a recent industry report, the global CNC lathe market is expected to grow by 6.1% annually, highlighting increasing demand for precision machining across various sectors. This trend underscores the importance of choosing a machine that not only fits your project needs but also offers the latest technological advancements.

For hobbyists and professionals alike, understanding your specific requirements is key. Whether you're interested in woodworking or metalworking, the right lathe will significantly influence your project's success. Industry experts recommend analyzing factors such as the lathe's size, speed, and type of tools it can accommodate. Furthermore, emerging CNC technologies offer enhanced capabilities, allowing you to take on diverse projects, from custom furniture to intricate automotive parts. By investing time in researching and consulting with experts, you can ensure your choice in lathe maximizes efficiency and quality in your machining endeavors.

The Future of CNC Lathe Alternatives: Trends and Developments

The future of CNC lathe alternatives is being shaped by emerging technologies and growing market demands. According to recent reports, the global CNC machine tools market is projected to grow by USD 21.9 billion from 2025 to 2029, primarily driven by the increasing requirement for high-precision and multi-axis machining centers. This surge is being accelerated by artificial intelligence, which is redefining the landscape of manufacturing and allowing for greater efficiency and accuracy in machining processes.

Moreover, the woodworking machinery market is also experiencing significant growth, with projections indicating an increase from $5.23 billion in 2025 to $7.88 billion by 2032, at a compound annual growth rate (CAGR) of 6.0%. This growth reflects a broader trend towards automation and the adoption of new technologies, which are revolutionizing the circular economy and promoting sustainable practices in manufacturing.

Both industries are witnessing transformative changes as new methodologies, including additive manufacturing and advanced automation, pave the way for a more efficient and sustainable future in industrial production.

Related Posts

-

Exploring Future Innovations in CNC Lathes for Global Manufacturers in 2025

-

Maximizing Cnc Lathes Longevity with Cost Effective Maintenance Strategies

-

Top 7 CNC Lathes That Revolutionize Precision Engineering

-

Crafted Precision Global Reach of Best Cnc Machine Tools from China

-

Exploring Options: What to Consider When Choosing Your Next CNC Tool Room Lathe

-

Future Trends in Global Market for Best Lathe Machine by 2025