How to Maximize Efficiency with a Cnc Tool Room Lathe in Your Workshop

In today's competitive manufacturing landscape, maximizing efficiency has become a critical objective for workshops utilizing advanced machinery. Among these, the Cnc Tool Room Lathe stands out as a pivotal tool that enhances precision and productivity. According to a recent industry report by the Association for Manufacturing Technology, CNC machines, including tool room lathes, have shown up to a 40% increase in operational efficiency compared to traditional manual lathes. This remarkable improvement is attributed to their ability to execute complex parts with minimal human intervention, drastically reducing cycle times. Furthermore, a survey conducted by the National Institute of Standards and Technology revealed that businesses integrating CNC technology experienced a 30% reduction in waste and rework. As a workshop owner or operator, understanding how to effectively utilize a Cnc Tool Room Lathe is essential not only for achieving superior performance but also for maintaining a competitive edge in the evolving manufacturing sector.

Understanding the Basics of CNC Tool Room Lathes for Optimal Performance

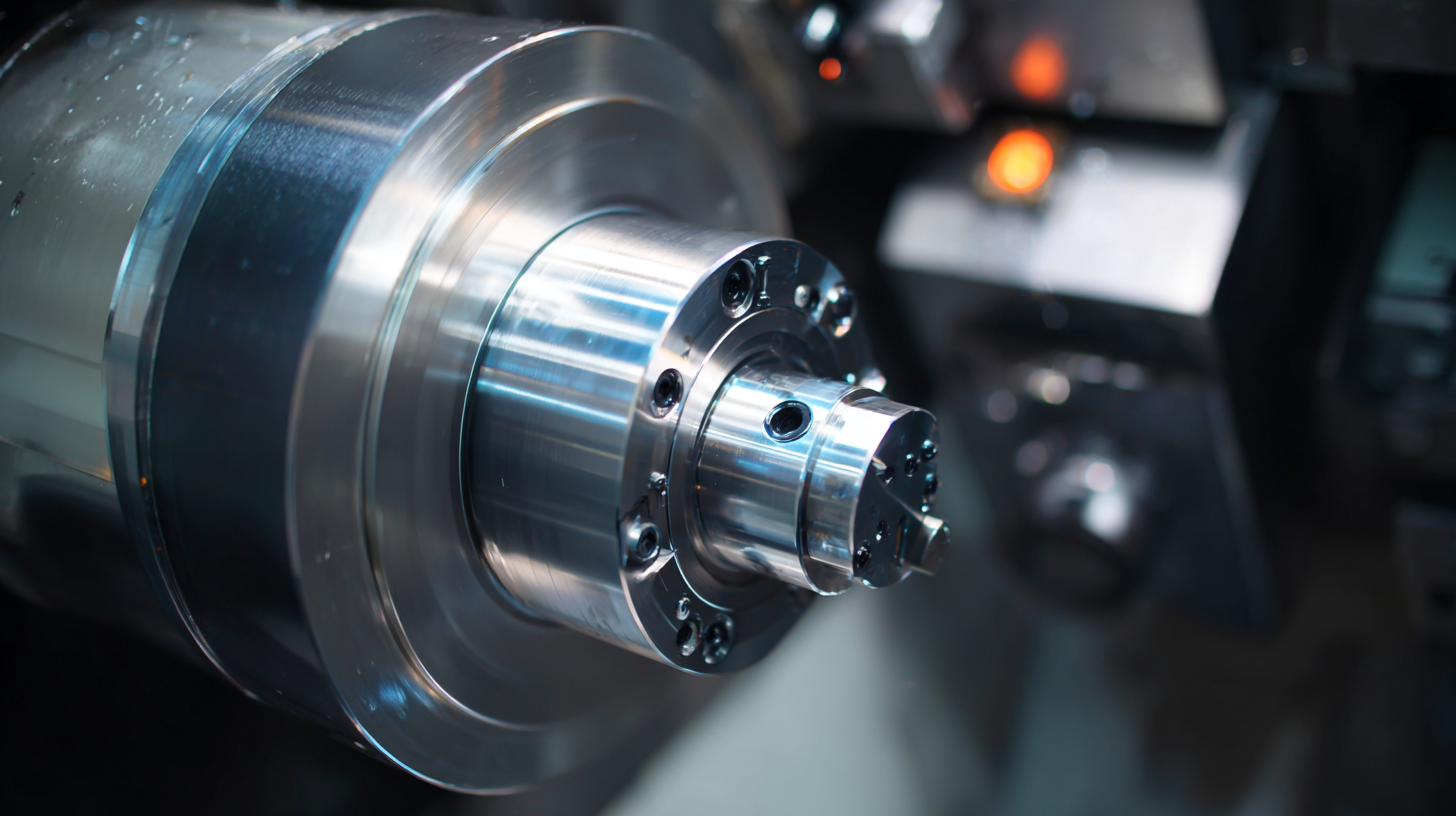

Understanding the basics of CNC tool room lathes is essential for optimizing their performance in any workshop. These advanced machines provide unparalleled precision and efficiency, especially when programmed to handle complex tasks. Key to maximizing their capabilities is familiarizing oneself with their programming interfaces and operational features, which can transform intricate design concepts into tangible components. For instance, the ability to automate the turning process can significantly reduce production times and minimize waste, particularly when dealing with diverse materials.

The challenges presented by turning hardened materials illustrate the potential of CNC lathes. With a capability to machine steels with hardness up to 68 HRC, these lathes not only address demanding projects but also open new avenues for production strategies. The evolution of CNC technology has made it possible for workshops to achieve high levels of customization and efficiency, allowing operators to produce complex geometries while maintaining high-quality standards. Embracing this technology ultimately leads to enhanced productivity and competitiveness in the metalworking industry.

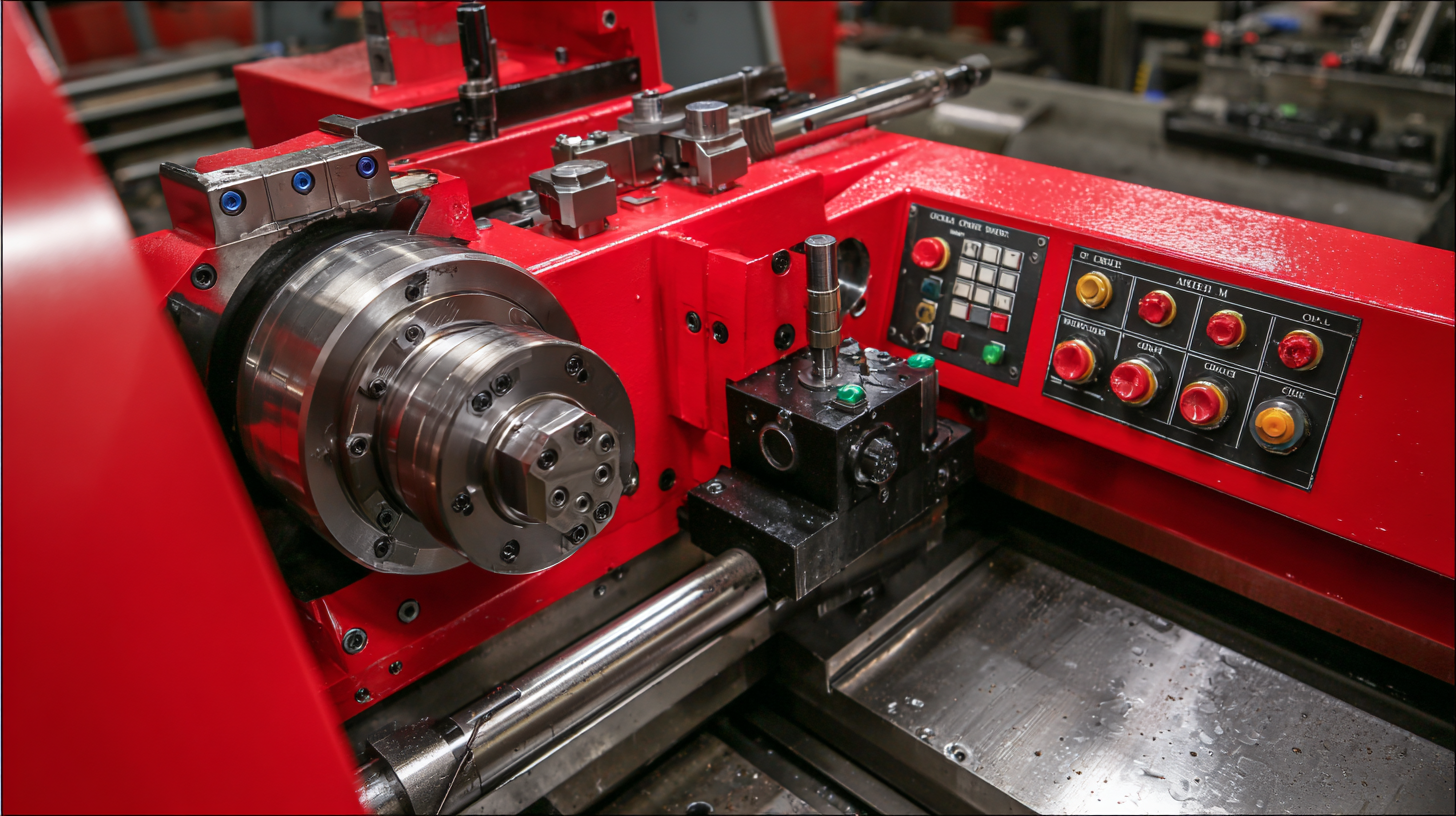

Key Features to Look for in a High-Quality CNC Tool Room Lathe

When selecting a high-quality CNC tool room lathe, there are several key features that can significantly enhance your workshop's efficiency. First and foremost is the machine's rigidity and stability, which are crucial for maintaining precision during the machining process. A robust frame, combined with high-quality components, minimizes vibrations and allows for consistent performance even under heavy workloads.

Another essential feature is the CNC control system. Look for a user-friendly interface that supports advanced programming capabilities, enabling you to efficiently produce complex parts. Additionally, consider models with real-time monitoring and feedback systems, which can help detect issues early and reduce downtime. Tools with automatic tool changers can also drastically speed up operations, as they reduce the time spent on manual setups between different machining tasks. Together, these features can lead to increased productivity and improved output quality in your workshop.

Maximizing Efficiency with CNC Tool Room Lathes

This chart illustrates the average efficiency improvement in various machining operations using a high-quality CNC tool room lathe. The data represents the percentage increase in efficiency compared to traditional lathes.

Techniques for Setting Up Your CNC Tool Room Lathe for Maximum Efficiency

Setting up your CNC tool room lathe for maximum efficiency is crucial for optimizing production and reducing waste. One key technique is to ensure that your workpiece is securely clamped to minimize vibration. According to a 2022 study by the American Society of Mechanical Engineers (ASME), setups with reduced vibration can enhance tool life by up to 30%, leading to fewer tool changes and more consistent machining quality.

Another critical aspect is the tool selection and arrangement. Utilizing a tool library that corresponds to the specific types of jobs you're executing allows for faster changes and setup times. A report from the National Institute of Standards and Technology (NIST) highlights that workshops employing CNC tool libraries saw a 15% increase in overall productivity.

Tips for efficiency: Ensure that your tool changes are as streamlined as possible by preparing all necessary tools beforehand. Additionally, keep a clean workspace, as clutter can lead to inefficiencies and errors during setup. Lastly, regularly update your CNC software to access the latest optimization features.

By focusing on these techniques, you can significantly improve the efficiency of your CNC tool room lathe, ultimately boosting your workshop's output and profitability.

Best Practices for Maintenance and Care of CNC Tool Room Lathes

To ensure optimal performance and longevity of CNC tool room lathes, regular maintenance and care are essential. One of the best practices is to keep the machine clean and free from debris, which can lead to wear and tear on crucial components. Daily cleaning routines should involve removing chips and coolant residue to prevent corrosion and ensure precise operations. Additionally, lubrication of moving parts is vital; this not only reduces friction but also extends the lifecycle of the equipment. Operators should follow the manufacturer's guidelines for lubrication intervals and types of lubricant to use.

Moreover, monitoring the machine's performance helps in early detection of potential issues. Implementing a preventative maintenance schedule can address small problems before they escalate into major repairs. Checking for signs of wear on tools and recalibrating the machine regularly are also fundamental steps to maintain accuracy. Operators should be trained to recognize abnormal sounds or vibrations that may indicate needed adjustments or repairs. By prioritizing these maintenance practices, workshops can maximize the efficiency of their CNC tool room lathes and optimize overall productivity.

How to Maximize Efficiency with a CNC Tool Room Lathe in Your Workshop - Best Practices for Maintenance and Care of CNC Tool Room Lathes

| Maintenance Task | Frequency | Best Practices | Tools Required |

|---|---|---|---|

| Clean the Machine | Daily | Remove chips and debris; use a vacuum | Vacuum; cleaning cloths |

| Lubrication | Weekly | Check oil levels and apply as needed | Lubricating oil; grease |

| Check Alignment | Monthly | Use dial indicators for precision | Dial indicator; measurement tools |

| Inspect Tooling | Bi-weekly | Check for wear and tear; replace if necessary | Wrenches; tool gauge |

| Software Updates | Quarterly | Install the latest software for optimal performance | Computer; internet access |

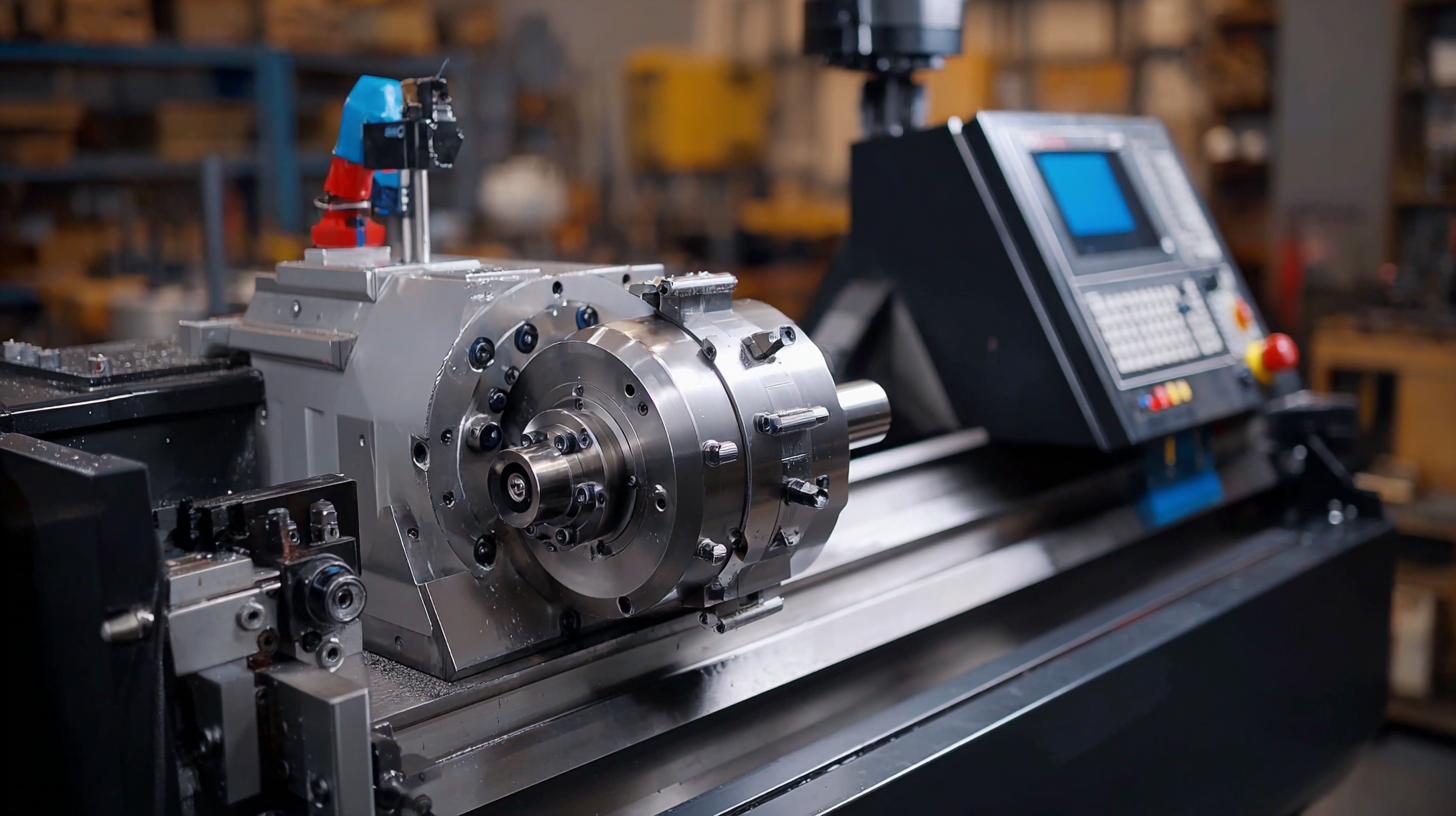

Tips for Integrating CNC Tool Room Lathes into Your Workshop Workflow

Integrating CNC tool room lathes into your workshop workflow requires careful consideration of both environmental conditions and operational efficiency. Today's machining shops are increasingly focused on maintaining optimal working environments, utilizing mist collectors and air cleansers to keep machines and operators cool and clean. This emphasis on cleanliness not only enhances safety but also improves the precision of machining operations, allowing for tighter tolerances and reduced cycle times.

Moreover, transitioning from manual to CNC lathes can significantly streamline workshop processes. Machines that operate in various modes—manual, semi-automatic, and fully CNC—offer flexibility and adaptability in production. Implementing custom control functions can further simplify routines and minimize errors, making it easier for operators to achieve desired results. By embracing these technologies and practices, workshops can maximize the efficiency of CNC tool room lathes, leading to cost savings and enhanced productivity in the long run.

Related Posts

-

Maximizing Cnc Lathes Longevity with Cost Effective Maintenance Strategies

-

Exploring Options: What to Consider When Choosing Your Next CNC Tool Room Lathe

-

Exploring Future Innovations in CNC Lathes for Global Manufacturers in 2025

-

Unlocking Precision: The Future of CNC Machining Centers for Global Buyers

-

Experience the Surge of Global Demand for Cnc Machine Tools at the Latest Canton Fair in Guangzhou

-

Crafted Precision Global Reach of Best Cnc Machine Tools from China