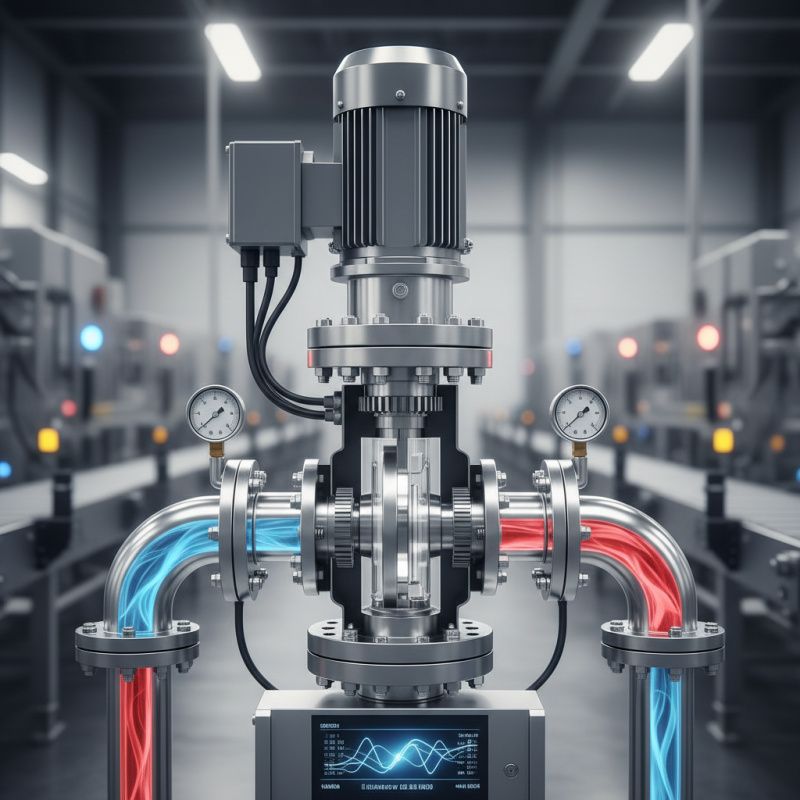

Motorized Valve Tips for Optimal Performance and Longevity?

Motorized Valves play a crucial role in modern industrial applications. They regulate the flow of liquids and gases with precision. According to a recent market report by ResearchAndMarkets, the global motorized valve market is projected to reach $5.2 billion by 2026, growing at a CAGR of 4.6%. This growth signifies the increasing reliance on automation and efficient flow control systems.

However, optimal performance and longevity of motorized valves are often overlooked. Regular maintenance is essential to prevent failures. A study by the American Society of Mechanical Engineers found that improper installation can reduce valve life by up to 40%. Operators need to be mindful of factors such as fluid type, temperature, and pressure. Overheating or corrosion can lead to significant wear and tear.

Despite advancements in technology, many systems still face issues. Users must reflect on their practices to enhance valve performance. Small adjustments, like sensor calibrations and software updates, can yield considerable benefits. Attention to detail in valve selection and proper integration is vital for longevity and operational efficiency in any system integrating motorized valves.

Motorized Valve Types and Their Applications in Modern Industries

Motorized valves play a crucial role in various industries. They are used to control the flow of fluids. Different types of motorized valves exist, each serving unique purposes. The three main types include ball valves, butterfly valves, and globe valves. Each has its strengths and weaknesses. For instance, ball valves work best for on/off applications, while butterfly valves excel in throttling.

In modern manufacturing, motorized valves are essential. They automate processes, improving efficiency. In water treatment, they regulate flow in treatment plants. Oil and gas industries rely on them for managing pressure and flow rates. However, installation and maintenance challenges often arise. Incorrect installation can lead to leaks or valve failure. Additionally, routine checks are necessary to ensure proper function.

While these valves significantly enhance operational performance, their limitations must not be overlooked. Over time, wear and tear affect their reliability. Factors such as temperature fluctuations and corrosive environments can lead to premature degradation. Regular assessments are necessary to address potential issues. Recognition of these factors can prolong the lifespan of motorized valves, preventing costly downtime.

Factors Influencing the Performance of Motorized Valves

Motorized valves play a crucial role in various industrial applications. Their performance hinges on several factors. The quality of materials used in construction impacts longevity significantly. For instance, stainless steel valves show better corrosion resistance than aluminum counterparts. This resistance is vital in chemical processing environments.

Another critical factor is the actuator type. Electric actuators often provide more precise control compared to pneumatic ones. Data indicates that systems with electric actuators achieve a 20% increase in efficiency. However, they can be more complex to maintain. The learning curve for operators can sometimes be steep.

Environmental conditions also influence valve performance. Extreme temperatures and pressure fluctuations can lead to premature failure. Consistent monitoring is essential. Studies show that regular maintenance can extend the lifespan of motorized valves by up to 30%. Yet, many facilities neglect this aspect, leading to unexpected downtime. Understanding these factors is essential for optimizing valve performance.

Motorized Valve Tips for Optimal Performance and Longevity

| Factor | Description | Impact on Performance | Recommended Practices |

|---|---|---|---|

| Temperature Range | The operational temperature limits for valve performance. | Affects the valve's movement speed and seal longevity. | Ensure compatibility with operating temperatures; use thermal insulation where necessary. |

| Fluid Compatibility | The suitability of the valve materials for the fluid type being controlled. | Protects against corrosion and wear, ensuring reliable operation. | Choose materials that resist chemical degradation; conduct regular inspections. |

| Actuation Speed | The speed at which the valve opens and closes. | Affects system response time and can lead to pressure surges. | Adjust actuator settings for optimal speed; avoid rapid cycling. |

| Power Supply Stability | Reliability of the electrical supply to the valve actuator. | Inconsistent power can cause malfunction or damage. | Use UPS systems to ensure stable power; perform regular voltage checks. |

| Maintenance Schedule | Regular inspection and maintenance checks of the valve. | Prevents unexpected failures and extends lifetime. | Implement a proactive maintenance routine; document all service records. |

Common Maintenance Practices for Enhancing Valve Longevity

Regular maintenance is crucial for enhancing the longevity of motorized valves. A recent industry report indicates that improper upkeep can lead to a 30% reduction in valve lifespan. This highlights the importance of following best practices. One effective strategy is routine inspection. Inspect the valve for leaks or unusual noises. These issues can signal potential failures.

Lubrication also plays a vital role. Keeping the moving parts well-lubricated reduces friction. It can help to avoid premature wear. According to research, valves that are properly maintained can operate efficiently for over ten years. However, many users skip this step, leading to cumbersome repairs down the line.

Cleaning is another essential practice. Dust and debris can impair valve function. Regular cleaning extends performance and minimizes malfunctions. Stray debris can create blockages. Address these concerns proactively. Neglecting routine maintenance may result in system inefficiencies. Overall, consistent care is imperative for optimizing valve performance and ensuring a longer operational life.

Industry Standards and Ratings for Motorized Valve Efficiency

Motorized valves play a critical role in various industrial applications. Their efficiency is often measured by industry standards. One prominent measure is the valve's flow coefficient (Cv). This metric helps determine the valve's performance under specific pressure conditions. Research shows that a higher Cv indicates better flow rates. However, many users overlook the importance of selecting valves that meet rigorous industry ratings.

The American Society of Mechanical Engineers (ASME) has set standards for valve testing and performance. According to recent reports, nearly 40% of motorized valves do not meet these standards during initial assessments. Poor installation and maintenance are often the leading causes. In factories, this can lead to inefficiencies and increased operational costs. Regular audits can identify these issues, preventing larger problems down the line.

Energy efficiency ratings are another important aspect. The industry has seen a shift towards integrating smart technologies into motorized valve systems. These innovations can optimize energy use, yet they require proper calibration. Studies indicate that improper settings can lead to a 15% reduction in efficiency. Users must pay attention to these details to ensure longevity and optimal performance.

Motorized Valve Efficiency Ratings

This bar chart illustrates the efficiency ratings of various motorized valve types based on their performance and longevity. The data reflects industry standards and provides insights into optimal choices for applications requiring reliable fluid control.

Future Trends in Motorized Valve Technology and Innovation

The future of motorized valve technology is evolving rapidly. Industry reports indicate a projected growth rate of 7.4% in the next five years. This growth is largely driven by advancements in automation and connectivity. Smart valves will likely become more commonplace. They promise better efficiency and precision in fluid management.

One notable trend is the integration of IoT technology. By 2025, it's expected that 50% of all motorized valves will feature smart sensors. These sensors can provide real-time data, enhancing operational safety. However, manufacturers face challenges in standardizing these technologies. Compatibility across devices remains a concern.

Additionally, sustainability is becoming a focal point. Many companies are prioritizing eco-friendly materials in production. This aligns with the growing demand for greener solutions in industrial processes. However, not all manufacturers are ready to adapt, posing potential risks. As innovation continues, thoughtful reflection on these challenges is crucial for long-term success.