Unlocking Precision in Manufacturing with Best Cnc Machine Tools Comprehensive Technical Specs and Usage Guide

As the manufacturing landscape continues to evolve, the role of CNC (Computer Numerical Control) machine tools has become increasingly critical for achieving precision and efficiency in production processes. According to a report by MarketsandMarkets, the global CNC machine tools market is expected to reach $118.6 billion by 2026, growing at a CAGR of 6.9% from 2021. This growth is driven by the increasing demand for high-quality, complex components across various industries, including aerospace, automotive, and electronics. The integration of advanced technologies such as automation and smart manufacturing is transforming the capabilities of CNC machine tools, allowing manufacturers to optimize their operations and enhance product quality. In this blog, we will delve into the comprehensive technical specifications and usage guidelines of the best CNC machine tools available, unlocking the potential for precision in modern manufacturing.

The Evolution of CNC Machine Tools: A Journey Through Technological Advancements

The evolution of CNC (Computer Numerical Control) machine tools has been a remarkable journey encompassing decades of technological advancements that have significantly transformed manufacturing processes.

Initially, CNC technology emerged in the 1950s as a method to automate machining tools, providing manufacturers with the ability to program precise operations. This innovation marked a pivotal shift, as it combined the efficiency of electronics with the intricacies of traditional machining, paving the way for increased production rates and enhanced accuracy.

As the years progressed, advancements in software and hardware played crucial roles in the evolution of CNC machine tools. The introduction of sophisticated CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems allowed for seamless transitions from design to production, enabling manufacturers to realize complex geometries with unparalleled precision.

Furthermore, the integration of IoT (Internet of Things) technologies has ushered in a new era of smart manufacturing, where CNC machines are not only automated but also interconnected, facilitating real-time monitoring and predictive maintenance.

This ongoing technological evolution continues to redefine the landscape of manufacturing, driving innovation and competitiveness in the industry.

Key Technical Specifications: Understanding What Makes a Great CNC Machine Tool

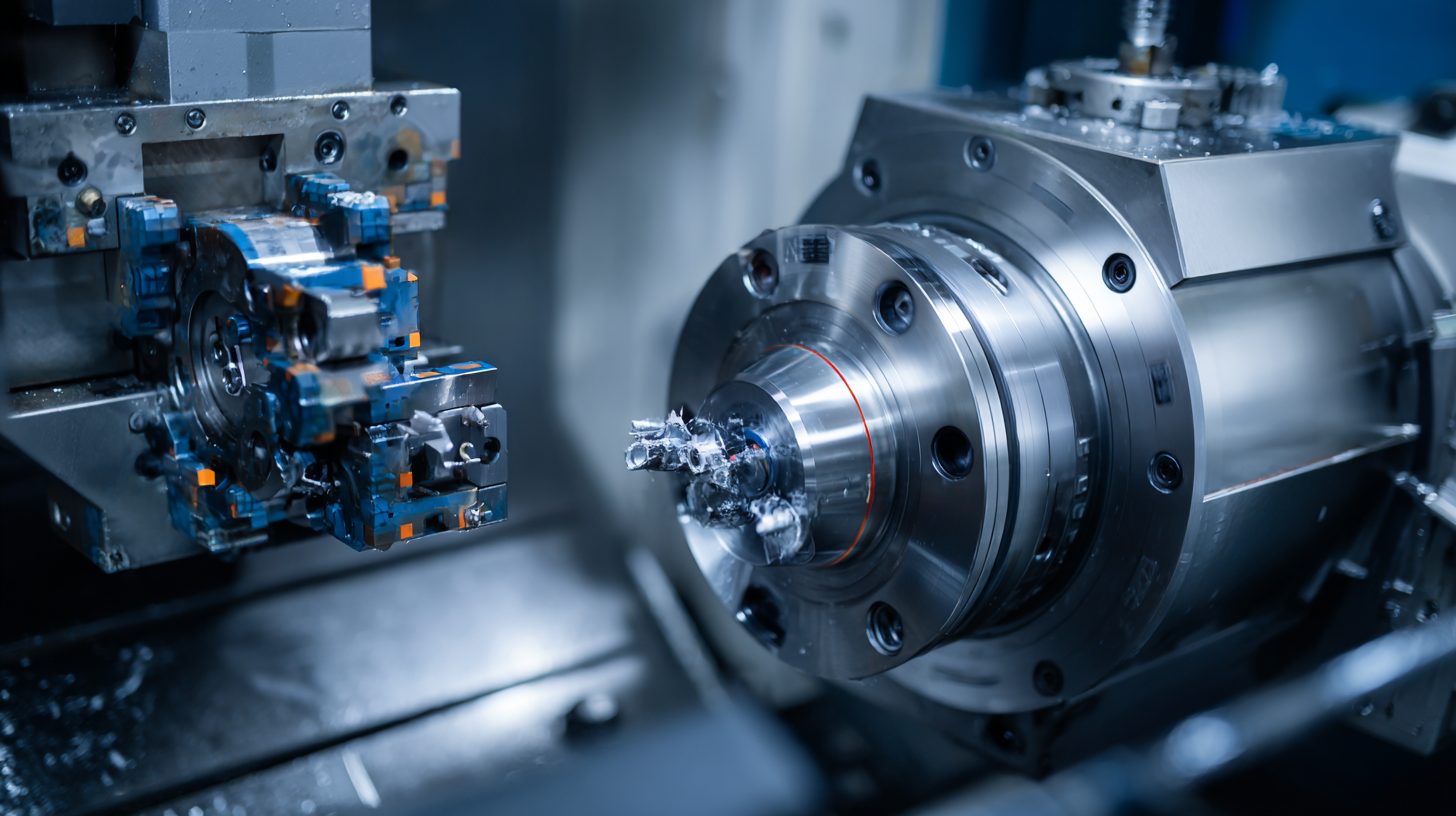

Understanding the key technical specifications of CNC machine tools is essential for manufacturers looking to enhance their production capabilities. These specifications include precision, speed, versatility, and automation features that are critical in today’s competitive landscape. Advanced CNC machines now incorporate digital manufacturing technologies that significantly uplift productivity benchmarks across various industries. For instance, features such as high-speed machining and real-time monitoring enable companies to achieve greater accuracy and minimize waste, leading to more efficient operations.

Moreover, the European CNC machine market is experiencing robust growth, driven by increasing automation and the rising demand for precise manufacturing processes. The incorporation of cyber-physical systems (CPS) is particularly noteworthy, as these models allow for intelligent manufacturing by analyzing vast amounts of electronic data. Machine learning algorithms are also being employed to refine process segmentation, which streamlines workflows and optimizes production timelines. As manufacturers adapt to these technological advancements, a clearer understanding of the specifications that define exceptional CNC machine tools will be pivotal for success in the evolving market landscape.

Choosing the Right CNC Machine: Factors to Consider for Precision Manufacturing

When selecting the right CNC machine for precision manufacturing, several critical factors come into play. With the global CNC machinery market projected to grow from $101.2 billion in 2025 to $195.59 billion by 2032, achieving optimal performance and efficiency is paramount for manufacturers looking to remain competitive. This anticipated growth, reflecting a substantial compound annual growth rate (CAGR) of 9.9%, underscores the increasing demand for advanced CNC solutions that deliver accuracy and reliability.

Key considerations for choosing CNC machines include the machine's specifications, such as spindle speed, feed rate, and tool capacity, which directly influence manufacturing precision. Additionally, compatibility with various materials and ease of integration into existing workflows are vital. As industry requirements continue to evolve, selecting a CNC machine that not only meets current needs but also adapts to future technological advancements will ensure sustained operational excellence. The projected expansion of the global machine tool market, expected to increase from $13.63 billion in 2025 to $22.946 billion by 2032, further emphasizes the importance of making informed decisions in CNC equipment investments.

Unlocking Precision in Manufacturing with CNC Machine Tools

This bar chart illustrates essential specifications for CNC machines, highlighting their accuracy, speed, reliability, and cost. Understanding these factors is crucial for selecting the right CNC machine for precise manufacturing tasks.

Best Practices for Utilizing CNC Technology in Modern Manufacturing Environments

In the fast-evolving landscape of modern manufacturing, leveraging CNC technology has become paramount for achieving precision and efficiency. Best practices for utilizing CNC machines involve a thorough understanding of the tools and their capabilities.

This begins with selecting the right CNC machine for specific applications, whether it’s milling, turning, or laser cutting. Each machine comes with unique specifications that cater to different materials and project requirements. Understanding these specs helps manufacturers make informed decisions that enhance the overall production process.

Another crucial aspect of maximizing CNC technology is the importance of operator training and maintenance. Skilled operators can exploit the full potential of CNC machines, from optimizing tool paths to fine-tuning feed rates, which ultimately leads to improved product quality and reduced waste. Regular maintenance and calibration of CNC equipment are equally essential to ensure consistent performance and longevity. By integrating these best practices into their workflows, manufacturers can not only elevate their production standards but also stay competitive in a rapidly changing market.

Future Trends in CNC Machining: Predicting the Next Innovations and Developments

The future of CNC machining is poised for revolutionary advancements that will reshape the manufacturing landscape. As industries increasingly focus on strengthening supply-chain resilience, the quest for innovative solutions is more critical than ever. Emerging trends suggest that the integration of advanced technologies, such as artificial intelligence and machine learning, will enhance precision and efficiency in CNC operations. The emphasis on sustainability will also drive innovation, as manufacturers aim to lower carbon footprints through smarter machining processes and energy-efficient designs.

China's rapid ascension as a leader in advanced manufacturing technologies highlights the global shift towards enhanced innovation capabilities. Chinese universities and companies are at the forefront of developing cutting-edge solutions that address complex manufacturing challenges. Additionally, insights from executive surveys reveal that 3D printing will continue to play a pivotal role in 2025 and beyond, revealing a growing consensus among leading firms about its potential to revolutionize production methods. As we look to the future, it is clear that the synergy between automation, precision tools, and sustainable practices will define the next era of manufacturing innovation.

Unlocking Precision in Manufacturing with Best CNC Machine Tools: Comprehensive Technical Specs and Usage Guide

| Feature | Specification | Usage Scenario |

|---|---|---|

| Working Area | 600 x 400 x 300 mm | Ideal for small to medium parts manufacturing |

| Spindle Speed | 0 - 24,000 RPM | Effective for high-speed machining of hard materials |

| Tool Holder Type | ER Collet | Allows for a quick tool change |

| Control System | CNC Controller with Touchscreen Interface | User-friendly operation and easy programming |

| Power Supply | 220V / 380V, 50/60Hz | Standard industrial electrical supply |

| Weight | 1,200 kg | Stable base for precision machining |