Ultimate Guide to Selecting the Right Tool Room CNC Mill for Your Manufacturing Needs

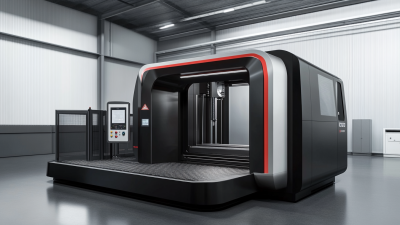

In today's competitive manufacturing landscape, selecting the appropriate Tool Room CNC Mill is crucial for optimizing production efficiency and product quality. According to a recent report by Statista, the global CNC machine market is projected to reach approximately $100 billion by 2025, driven by increasing automation and the need for precision in manufacturing processes. With advancements in technology, Tool Room CNC Mills now offer enhanced capabilities, allowing for complex machining tasks with superior accuracy.

As manufacturers face rising demands for customized parts and shorter lead times, understanding how to choose the right Tool Room CNC Mill becomes imperative. This guide will explore the essential factors to consider, ensuring that your investment meets the specific requirements of your operations and contributes positively to your bottom line.

As manufacturers face rising demands for customized parts and shorter lead times, understanding how to choose the right Tool Room CNC Mill becomes imperative. This guide will explore the essential factors to consider, ensuring that your investment meets the specific requirements of your operations and contributes positively to your bottom line.

Understanding the Basics of Tool Room CNC Mills and Their Applications

When selecting a tool room CNC mill, it's essential to understand the unique capabilities and applications of these machines. Tool room CNC mills are primarily designed for precision machining tasks, making them ideal for job shops that require high accuracy and versatility in producing intricate parts. From creating precision ceramic components to manufacturing complex geometries, these mills can adapt to various materials and designs, catering to a wide range of industry needs.

Recent advancements in CNC technology have further broadened the application scope for tool room mills. Innovations in digitalization and machine capabilities allow for a seamless integration of CNC milling into modern manufacturing workflows. For instance, the introduction of custom control functions and advanced user interfaces helps streamline operations, reducing potential errors and enhancing productivity. Furthermore, trends such as the growing popularity of Swiss-type machining indicate a shift towards multifunctionality, where conventional and specialized CNC machines coexist to tackle diverse manufacturing challenges more effectively.

Key Features to Consider When Choosing a Tool Room CNC Mill

When selecting a tool room CNC mill, understanding the key features that impact performance and usability is crucial. One of the primary considerations is the precision of the machining process, which can significantly influence the quality of the final product. Look for mills equipped with advanced spindle technologies and integrated sensor systems that monitor machining signals in real-time. These features ensure consistent outputs and help in identifying any issues early on during production, enhancing operational efficiency.

Another important aspect is the software compatibility of the CNC mill. It's essential to choose a machine that supports user-friendly control systems or open-source firmware like GRBL, which provides precise control over the milling process. This allows for flexibility in programming and improved adaptability to various manufacturing needs. Furthermore, assess the tool wear prediction capabilities of the mill; advanced predictive algorithms can prevent unexpected downtime by anticipating and mitigating wear before it affects operation. By focusing on these key features, manufacturers can significantly enhance their efficiency and product quality in tool room applications.

Comparing Different CNC Mill Brands and Models for Optimal Performance

When selecting a CNC mill for your tool room, understanding the performance metrics of various brands and models is essential for making an informed decision. According to a recent report from the Manufacturing Technology Association, CNC machines equipped with advanced controls can enhance production efficiency by up to 25%, especially models from established brands like Haas and Mazak. These companies are known for their robust engineering and reliability, contributing to lower cycle times and improved precision in machining operations.

Furthermore, a study by the American Machine Tool Distributors' Association indicated that over 60% of manufacturers prefer CNC mills that offer easy integration with CAD/CAM software. Brands like Okuma and Fanuc provide user-friendly interfaces, which can lead to a significant reduction in training time and faster implementation of production workflows. Ultimately, examining the performance benchmarks, software compatibility, and after-sales support of different CNC mill models can guide you to invest in equipment that aligns effectively with your manufacturing goals.

Evaluating Your Manufacturing Needs and Budget Constraints

When selecting the right tool room CNC mill for your manufacturing needs, understanding your specific requirements and budget constraints is paramount. Start by evaluating the types of projects you will be undertaking. Consider factors such as the materials you will use, the required precision, and the complexity of your designs. Different CNC mills offer varying capabilities, from basic machining tasks to advanced multi-axis operations, which can greatly influence productivity and end results.

Once you have a clear picture of your manufacturing needs, aligning these with your budget becomes critical. High-end CNC mills might boast superior technology and features, but they come with a heftier price tag. Conversely, entry-level models are often more affordable but may not meet all your operational demands. It's essential to strike a balance between cost and functionality. Investing in a machine that meets your current needs while allowing for future growth can save you money and headaches down the line, ensuring that your manufacturing processes remain agile and efficient.

Tips for Maintaining and Optimizing Your CNC Mill for Longevity

When investing in a CNC mill for your manufacturing needs, focusing on maintenance and optimization is crucial for maximizing its longevity and performance. Regular upkeep can significantly enhance the lifespan of your equipment, ensuring that it operates at peak efficiency. A recent report predicts the CNC machining services market to exceed $56 billion by 2024, driven by rising demands for precision and reliability in manufacturing processes.

To maintain your CNC mill effectively, consider implementing a routine inspection schedule. Checking for wear and tear on critical components, replenishing lubricants, and recalibrating tools can prevent unexpected downtime. Additionally, utilizing software for predictive maintenance can help to anticipate issues before they escalate, saving on repair costs and extending machine life.

Another essential tip is to optimize your machining parameters. Adjusting feed rates, spindle speeds, and tooling can not only improve production efficiency but also reduce the strain on the machine. With the right strategies, companies can expect a compound annual growth rate of over 4.1% between 2025 and 2034 in infrastructure maintenance services, underscoring the importance of investing in durable and well-maintained CNC machines.

Related Posts

-

7 Reasons Why CNC Machining Centers Are Essential for Modern Manufacturing Success

-

Unlocking Precision: The Future of CNC Machining Centers for Global Buyers

-

Experience the Surge of Global Demand for Cnc Machine Tools at the Latest Canton Fair in Guangzhou

-

Unveiling the Secrets to Finding Quality Suppliers for Best CNC Machine Service

-

Unlocking Precision in Manufacturing with Best Cnc Machine Tools Comprehensive Technical Specs and Usage Guide

-

Comprehensive Guide to Different Types of CNC Machining Centers and Their Applications