What is stainless steel woven wire mesh and its uses?

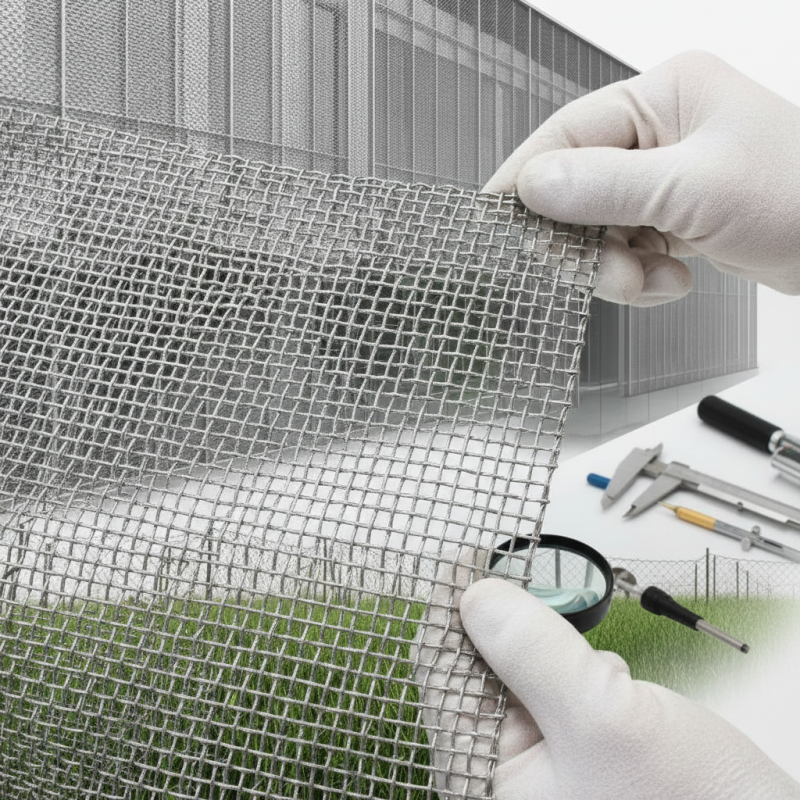

stainless steel woven wire mesh is a versatile material widely used across various industries. Renowned expert Dr. John Smith, a leader in materials engineering, remarked, "Stainless steel woven wire mesh represents the intersection of innovation and utility." This mesh is crafted by weaving stainless steel wires together, creating a durable and flexible structure. Its applications range from filtration to architectural uses, making it vital in multiple sectors.

In construction, stainless steel woven wire mesh offers strength and design elegance. It enhances both functionality and aesthetic appeal in building facades. In agriculture, it is utilized for pest control and crop protection. The mesh allows airflow while keeping unwanted animals at bay. However, the manufacturing process can sometimes yield inconsistencies in quality. These imperfections challenge users to evaluate their specific requirements more carefully.

Moreover, the mesh’s durability can lead some to overlook the need for periodic maintenance. This oversight might lead to premature wear or reduced effectiveness. As industries evolve, so does the demand for high-quality stainless steel woven wire mesh. Its ever-growing significance underscores the importance of understanding its properties and applications.

What is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is a versatile material. It consists of woven stainless steel strands, providing strength and durability. This mesh is well-known for its corrosion resistance. It can withstand harsh environments effectively. Many industries prefer stainless steel due to its long-lasting properties.

In construction and architecture, stainless steel woven wire mesh is commonly used. It serves as partitions and safety barriers. This mesh maintains aesthetic appeal while ensuring safety. In the food industry, it is used for sieving and filtration. The fine openings allow for precise filtering while preventing contaminants.

However, it is essential to consider the specific application when selecting mesh types. Not all stainless steel meshes suit every need. Some may require higher tensile strength, while others prioritize fine filtration. Reflecting on these factors can help avoid costly mistakes. Each application demands unique specifications and design considerations. It's wise to review options thoroughly before making a decision.

Composition and Properties of Stainless Steel Wire Mesh

Stainless steel woven wire mesh is a versatile material widely used across various industries. Its composition primarily includes stainless steel alloys, typically nickel and chromium. These elements provide excellent corrosion resistance. The mesh is durable, which makes it suitable for long-term applications. Its strength can withstand significant loads and stress. The mesh comes in different sizes and thicknesses, allowing for countless applications.

The properties of stainless steel wire mesh are notable. It exhibits high tensile strength and is resistant to various chemicals. This adaptability makes it ideal for filtration processes in food and beverage industries. It is also utilized in construction for safety barriers and architectural designs. However, its manufacturing can sometimes lead to inconsistencies in quality. The weaving process may leave gaps or imperfections in the mesh, challenging its overall effectiveness in specific applications.

Moreover, stainless steel wire mesh is easy to clean and maintain. Its smooth surface helps prevent the accumulation of dirt and bacteria. Yet, selecting the right mesh for the task is crucial. Users often struggle with matching mesh size to intended use. An incorrect choice can render the mesh less functional. Overall, while stainless steel woven wire mesh has many advantages, careful consideration in application is essential to maximize its effectiveness.

Stainless Steel Wire Mesh Properties and Uses

Common Manufacturing Techniques for Stainless Steel Mesh

Stainless steel woven wire mesh is produced using various methods. Common manufacturing techniques include weaving, welding, and powder coating. Each technique provides unique properties to the final product.

Weaving is the most traditional method. Thin stainless steel wires are interlaced to create a durable, flexible mesh. This technique results in a product with excellent filtration properties. It is widely used in construction and environmental applications. The process can be quite intricate, requiring skilled labor.

Welding offers another approach. In this method, wires are fused together at junctions. This creates a very strong mesh, ideal for heavy-duty applications. However, the welded sections may be prone to corrosion if not treated properly. Powder coating can provide extra protection. This technique coats the mesh with a layer of protective material, enhancing durability. Yet, this adds cost to the overall production.

Each of these methods has its challenges. The selection often depends on the intended use of the mesh. Do some research before choosing a method. Consider aspects like strength, flexibility, and potential corrosion. These factors will dictate the effectiveness of the final product.

What is stainless steel woven wire mesh and its uses? - Common Manufacturing Techniques for Stainless Steel Mesh

| Type of Mesh | Wire Diameter (mm) | Aperture Size (mm) | Common Uses | Manufacturing Technique |

|---|---|---|---|---|

| Plain Weave | 0.5 | 1.0 | Filtration, sieving | Woven Technique |

| Twilled Weave | 0.8 | 1.5 | Mining, oil & gas | Woven Technique |

| Dutch Weave | 0.6 | 0.5 | Precision filtration | Woven Technique |

| Wire Mesh Sheets | 1.0 | 2.0 | Construction, industrial uses | Laser Cutting, Shearing |

| Wire Mesh Panels | 1.5 | 3.0 | Fencing, security barriers | Welding |

Key Applications of Stainless Steel Woven Wire Mesh in Industry

Stainless steel woven wire mesh is a versatile material used across various industries. Its unique properties, such as corrosion resistance and strength, make it ideal for multiple applications. This mesh is often found in construction, filtration, and food processing, among other fields.

In the construction industry, stainless steel woven wire mesh supports structural integrity. It is used for reinforcing concrete and provides durability to buildings. In filtration, this mesh serves in water treatment plants, effectively filtering out impurities. It can withstand harsh chemicals and high temperatures, which is a significant advantage.

Food processing facilities also rely on stainless steel woven wire mesh. It is used for conveyor belts and screens, ensuring hygiene and safety. However, some operators struggle with proper maintenance. Regular cleaning is essential to prevent contamination. This often requires time and effort, which can be overlooked. Finding the right balance between durability and care is crucial for optimal performance.

Advantages of Using Stainless Steel Wire Mesh Over Other Materials

Stainless steel woven wire mesh is versatile and durable. Many industries utilize it for various applications. Its strength and resistance to corrosion make it a popular choice. Unlike plastic or other materials, stainless steel offers superior longevity. The wires are tightly woven, creating a strong barrier that retains shape under pressure.

One significant advantage is its ability to withstand extreme temperatures. In high-heat environments, stainless steel maintains structural integrity. This resistance to thermal expansion helps avoid warping, ensuring a consistent performance. Additionally, it excels in outdoor settings, where weather exposure can lead to deterioration. Stainless steel mesh can endure oxidation and moisture, unlike many alternatives.

Another point to consider is maintenance. While stainless steel is low-maintenance, it still requires occasional cleaning. Over time, dirt or debris can accumulate on the surface. Although it resists staining, neglect can lead to tarnishing. It's essential to periodically check for signs of wear. This attention to detail ensures optimal performance and longevity.