Top 7 CNC Lathes That Revolutionize Precision Engineering

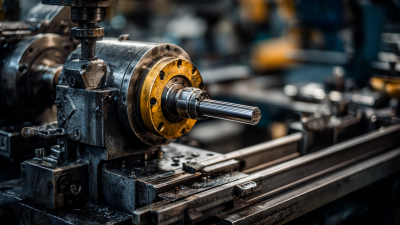

In the rapidly evolving landscape of precision engineering, CNC lathes have emerged as indispensable tools that significantly enhance manufacturing efficiency and product quality. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2026, growing at a CAGR of 6.6% from 2021, underscoring the increasing reliance on these sophisticated machines. CNC lathes offer unparalleled accuracy and repeatability, allowing manufacturers to produce complex components that meet stringent industry standards. With advancements in technology, the latest CNC lathes incorporate features such as automation, enhanced software capabilities, and improved energy efficiency, further revolutionizing the manufacturing process. In this blog, we will explore the top seven CNC lathes that are setting new benchmarks in precision engineering, showcasing how they can transform production lines and drive innovation across various sectors.

The Evolution of CNC Lathe Technology: Key Developments

The evolution of CNC lathe technology has been nothing short of revolutionary, significantly enhancing precision engineering. As manufacturing demands escalate, CNC lathes have undergone remarkable transformations. Early models were largely mechanical, but advancements in computer technology have enabled the development of advanced CNC systems that interface seamlessly with CAD software. This integration allows for precise control over machining processes, minimizing human error and maximizing efficiency.

Tip: When selecting a CNC lathe, consider the control software compatibility with your existing design systems. This will streamline your workflow and improve productivity.

Additionally, the introduction of multi-axis lathes has transformed the capabilities of CNC machining. These machines allow for complex geometries and intricate designs to be produced in a single setup, servicing a broader range of applications in various industries.

Tip: Regularly updating your CNC lathe's software can unlock new features and improve machine performance, keeping you competitive in the ever-evolving market.

Overall, as CNC lathe technology continues to evolve, engineers must stay informed about these developments to leverage them effectively in their projects.

Top 7 CNC Lathes That Revolutionize Precision Engineering

| Model | Max Turning Diameter (mm) | Max Turning Length (mm) | Spindle Speed (rpm) | Accuracy (mm) | Control System |

|---|---|---|---|---|---|

| CNC Lathe A | 500 | 1000 | 3000 | 0.01 | Fanuc |

| CNC Lathe B | 600 | 1200 | 2500 | 0.005 | Siemens |

| CNC Lathe C | 400 | 800 | 3500 | 0.01 | Mitsubishi |

| CNC Lathe D | 550 | 1100 | 2800 | 0.008 | Okuma |

| CNC Lathe E | 480 | 950 | 3200 | 0.007 | Fanuc |

| CNC Lathe F | 530 | 1150 | 3000 | 0.009 | Siemens |

| CNC Lathe G | 620 | 1300 | 2700 | 0.006 | Mitsubishi |

Understanding Precision Engineering: The Role of CNC Lathes

Precision engineering is a critical component in numerous industries, from aerospace to medical equipment manufacturing. CNC lathes play a transformative role in this field by enabling manufacturers to produce components with utmost accuracy. According to a 2022 report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2025, driven by advancements in precision machining technologies. This increase emphasizes the importance of high-quality CNC lathes, which help reduce production time while improving part quality.

Precision engineering is a critical component in numerous industries, from aerospace to medical equipment manufacturing. CNC lathes play a transformative role in this field by enabling manufacturers to produce components with utmost accuracy. According to a 2022 report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2025, driven by advancements in precision machining technologies. This increase emphasizes the importance of high-quality CNC lathes, which help reduce production time while improving part quality.

When selecting CNC lathes, it's crucial to consider factors such as spindle speed and feed rate. For optimal performance, ensure that the spindle speed aligns with the material type; for example, higher speeds are essential when working with softer metals, while harder materials may require slower speeds.

Tip: Regular maintenance of CNC lathes can extend their lifespan and maintain precision. Implement a routine inspection program that includes checking the alignment and calibration of your machine.

Moreover, integrating automated systems with CNC lathes enhances precision significantly. A study conducted by the International Journal of Advanced Manufacturing Technology noted that automation can improve production efficiency by up to 30%. This highlights the need for manufacturers to adopt smart machinery to keep up with competitive standards.

Tip: Invest in training your operators on the latest CNC technologies, as skilled personnel can leverage these advancements to maximize production efficiency.

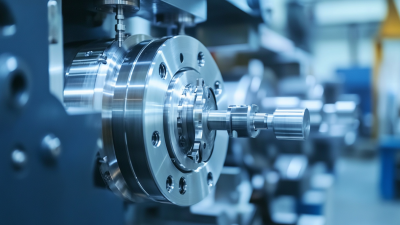

Top Features to Look for in a High-Performance CNC Lathe

When selecting a high-performance CNC lathe, several key features can significantly enhance precision engineering. First and foremost, consider the spindle speed and torque capabilities. A lathe with a high spindle speed allows for quicker machining cycles and improved material processing. Additionally, adequate torque is essential for handling tough materials without compromising quality. This combination ensures that the lathe can operate efficiently across a range of applications while maintaining precision.

Another important feature to look for is the control system. An advanced CNC control system should offer intuitive programming interfaces and support for various machining operations. Features such as live tooling and C-axis control enable multi-tasking capabilities and complex geometries, setting a high-performance CNC lathe apart from standard models. Moreover, robust feedback mechanisms and precise motion control contribute to consistent accuracy, making it easier to achieve tight tolerances required in precision engineering. A reliable cooling system and effective chip management further enhance operational efficiency, ensuring that the machine runs smoothly and maintains performance over long production runs.

Comparative Analysis of Leading CNC Lathes in the Market

The CNC (Computer Numerical Control) machine market is experiencing significant growth, projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust CAGR of 9.9%. This growth is fueled by the increasing demand for high-precision engineering solutions across various industries. Among these solutions, CNC lathes stand out for their ability to deliver unparalleled precision and efficiency in manufacturing processes.

When selecting a CNC lathe, consider the size and complexity of your projects. A versatile machine can handle various materials and intricate designs, which is essential for industries requiring precision engineering. Additionally, evaluating the machine's software capabilities is crucial, as advanced controls can significantly enhance productivity and reduce setup times.

Moreover, investing in the right accessories, such as high-quality cutting tools and automation features, can optimize your machining operations. As the CNC market continues to evolve with innovations, staying informed about the latest technology trends will ensure your business remains competitive in this rapidly expanding sector.

Top 7 CNC Lathes Precision Score Comparison

Future Trends in CNC Lathe Design and Precision Engineering

As the landscape of CNC lathe design evolves, the integration of high precision robotic milling techniques stands out as a significant trend shaping the future of precision engineering. Industries are increasingly turning to advanced machining processes that leverage robotics to improve efficiency and accuracy. These innovations not only enhance the capability of CNC lathes but also streamline workflow by reducing the complexities involved in machining intricate parts. The focus on robot trajectory planning and workspace analysis addresses challenges like vibration control and process optimization, leading to remarkable improvements in production quality.

Moreover, the shift towards robotic milling is indicative of a broader trend in precision engineering that emphasizes automation and adaptability. With the ability to perform complex machining tasks with reduced manual intervention, manufacturers can achieve higher levels of precision while minimizing errors. This evolution in CNC lathe design is paving the way for a future where machine intelligence and adaptive processes become standard, enabling engineers to push the boundaries of what is possible in precision manufacturing. As these trends continue to unfold, the implications for both productivity and innovation in the industry are profound, setting the stage for a new era of engineering excellence.

Related Posts

-

Maximizing Cnc Lathes Longevity with Cost Effective Maintenance Strategies

-

Exploring Future Innovations in CNC Lathes for Global Manufacturers in 2025

-

Exploring Options: What to Consider When Choosing Your Next CNC Tool Room Lathe

-

Innovative Manual Lathe Applications in Modern Manufacturing

-

7 Essential Tips for Choosing the Right Milling Machine Tools

-

Future Trends in Global Market for Best Lathe Machine by 2025