Top Strategies for Selecting the Best Measuring Equipment for Your Business

In today's competitive landscape, selecting the right measuring equipment is crucial for businesses aiming to uphold quality and precision in their operations. As highlighted in the 2022 Global Measuring Equipment Market report, the market is anticipated to reach a value of $30 billion by 2027, driven by increased demand for accurate measuring solutions across various industries. This growth reflects the industry's shift towards adopting advanced technologies that enhance quality control, particularly in manufacturing sectors. With China positioning itself as a leader in manufacturing excellence—earned through a commitment to quality—investing in state-of-the-art measuring equipment is vital for companies seeking to win global respect. By carefully choosing the appropriate tools, businesses can optimize their processes, ensure compliance with international standards, and ultimately, bolster their reputation in the market.

Key Factors to Consider When Choosing Measuring Equipment for Your Business

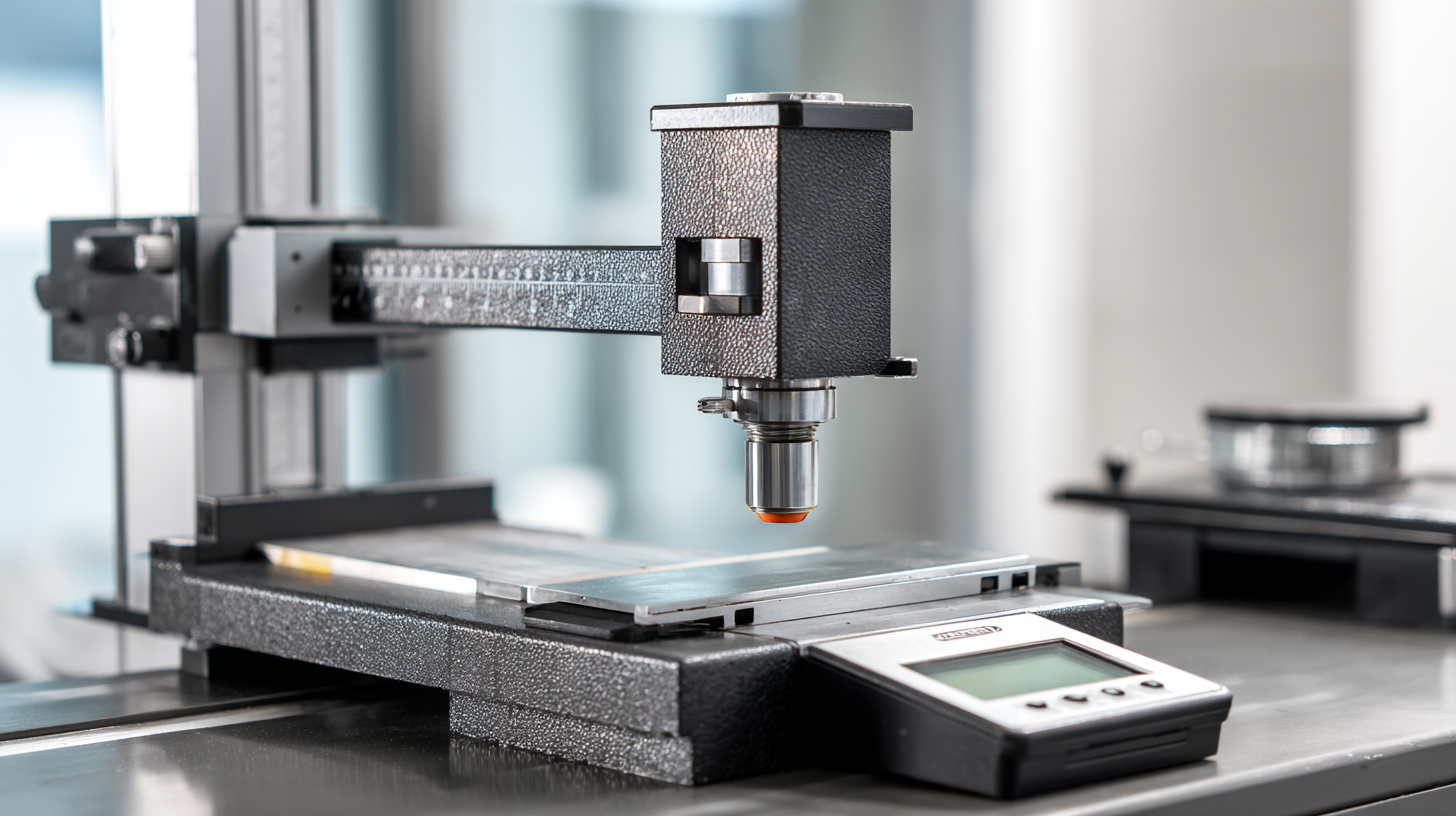

Selecting the right measuring equipment for your business

is crucial in achieving operational efficiency and ensuring high-quality standards.

As industries evolve, key factors such as accuracy, durability, and ease of use become paramount.

For instance, the global precision resistor market is projected to grow from $4.35 billion in 2022 to $6.4 billion by 2029, reflecting a compound annual growth rate (CAGR) of 5.7%.

This growth underlines the increasing importance of precise measurement tools within various sectors, especially in the

semiconductor testing and packaging industries.

When choosing measuring equipment, businesses must consider the application and specificity of their needs.

Testing equipment, especially in semiconductor packaging, plays a vital role in maintaining both product quality and process efficiency.

The rapid rise of domestic production in the testing equipment industry highlights the shift toward localized solutions, providing businesses with reliable options.

Additionally, the infrared detector market is anticipated to expand from $542 million in 2023 to approximately

$867.9 million by 2030, with a CAGR of 7%. Such trends indicate that investing in the

right measurement tools is essential for staying competitive in an increasingly technology-driven market.

Understanding the Impact of Technology on Measuring Equipment Selection

When selecting measuring equipment for your business, understanding the impact of technology is crucial. The rapid advancements in technology have streamlined processes, improved accuracy, and enhanced the capability of measuring tools. Businesses must stay informed about innovations like digital sensors and automated measurement systems, which can significantly reduce human error and increase efficiency in data collection.

Tip: Always assess the technological compatibility of new equipment with your existing systems. This ensures that the selected measuring tools can integrate smoothly without causing disruptions, giving you a seamless workflow and accurate results.

Moreover, analyzing the software provided with measuring equipment is essential. Modern devices often come with advanced analytics tools that allow for better data interpretation and reporting. This capability can transform raw measurements into actionable insights, helping businesses make informed decisions.

Tip: Evaluate the user-friendliness of the software interfaces. Equipment that is easy to operate will save time during training and lead to more consistent data usage across your team. Embracing such technology not only enhances measuring efficiency but also can give your business a competitive edge.

Top Strategies for Selecting the Best Measuring Equipment for Your Business

| Criteria | Description | Technology Impact | Example Equipment |

|---|---|---|---|

| Accuracy | The degree to which a measured value reflects the actual value. | Advanced sensors improve data precision. | Digital Calipers |

| Ease of Use | User-friendliness of the equipment, including interfaces. | Touchscreen interfaces simplify operation. | Laser Distance Measurer |

| Durability | The equipment's ability to withstand wear, pressure, or damage. | Rugged designs offer enhanced lifespan. | Industrial Multimeter |

| Cost Efficiency | The return on investment of the equipment over time. | Smart technologies reduce operational costs. | Smart Scales |

| Versatility | Ability to perform multiple tasks or measurements. | Multi-function devices streamline processes. | Combination Measuring Tools |

Evaluating Accuracy and Precision: Why They Matter in Your Business

When selecting measuring equipment for your business, evaluating accuracy and precision is vital. Accuracy refers to how close a measurement is to the true value, while precision indicates the consistency of repeated measurements. These two aspects are critical not only for ensuring product quality but also for maintaining trust with customers. Inaccurate measurements can lead to material waste, rework costs, and potential design flaws, all of which can negatively impact your bottom line.

Moreover, the right measuring equipment can enhance operational efficiency by minimizing errors and saving time. For example, using highly precise instruments can improve workflow by minimizing the need for adjustments and corrections. When investing in measuring equipment, consider the application environment and the specific metrics your business needs to assess. Take time to evaluate different devices, checking their calibration, technology, and user ease, as these factors significantly contribute to the overall effectiveness of your measurement strategy.

Measuring Equipment Accuracy and Precision Assessment

This bar chart compares the accuracy and precision of different measuring equipment. Accurate equipment provides results that are close to the true value, while precise equipment provides consistent results over repeated measurements. Selecting the right equipment is crucial for reliable business outcomes.

Cost-Effectiveness vs. Quality: Finding the Right Balance in Measurement Tools

When selecting measuring equipment for your business, striking the right balance between cost-effectiveness and quality is crucial. Businesses, especially small ones, face constant pressure to manage expenses without compromising on the tools that contribute to overall productivity. By leveraging innovative technologies and smart purchasing strategies, companies can find measurement tools that not only meet budget constraints but also maintain high performance standards. For instance, investing in versatile measuring instruments that enhance efficiency can lead to significant long-term savings.

Moreover, it's essential to understand the implications of quality in measurement tools. High-quality measuring equipment can minimize errors and enhance precision, ultimately leading to better decision-making and resource management. The challenge lies in evaluating whether the higher upfront costs of quality equipment will yield sufficient returns in reduced operational errors and improved efficiency.

To address this, businesses should conduct thorough cost-benefit analyses and consider the impact of their choices on employee engagement. Engaged employees working with reliable tools are more likely to contribute positively to the company's objectives, making the initial investment worthwhile in the broader picture of operational success.

Future Trends in Measuring Equipment: What to Expect in the Next Decade

As industries evolve, the future of measuring equipment is poised for significant advancements over the next decade. Key trends will revolve around the integration of smart technology, enabling devices to not only measure but also analyze and communicate data in real time. This will facilitate a more proactive approach to decision-making, allowing businesses to respond swiftly to operational changes and improve efficiency.

Additionally, the rise of automation in manufacturing and logistics will drive demand for more precise and reliable measuring tools. Expect to see the incorporation of IoT (Internet of Things) capabilities, which will enable seamless connectivity between devices and provide comprehensive insights. This trend will transform how companies monitor their processes, reducing downtime and enhancing productivity.

As these technologies emerge, selecting measuring equipment that embraces these innovations will be essential for businesses aiming to stay competitive in a rapidly changing landscape.