Exploring Unique Alternatives to the Best Lathe and Milling Machine Options

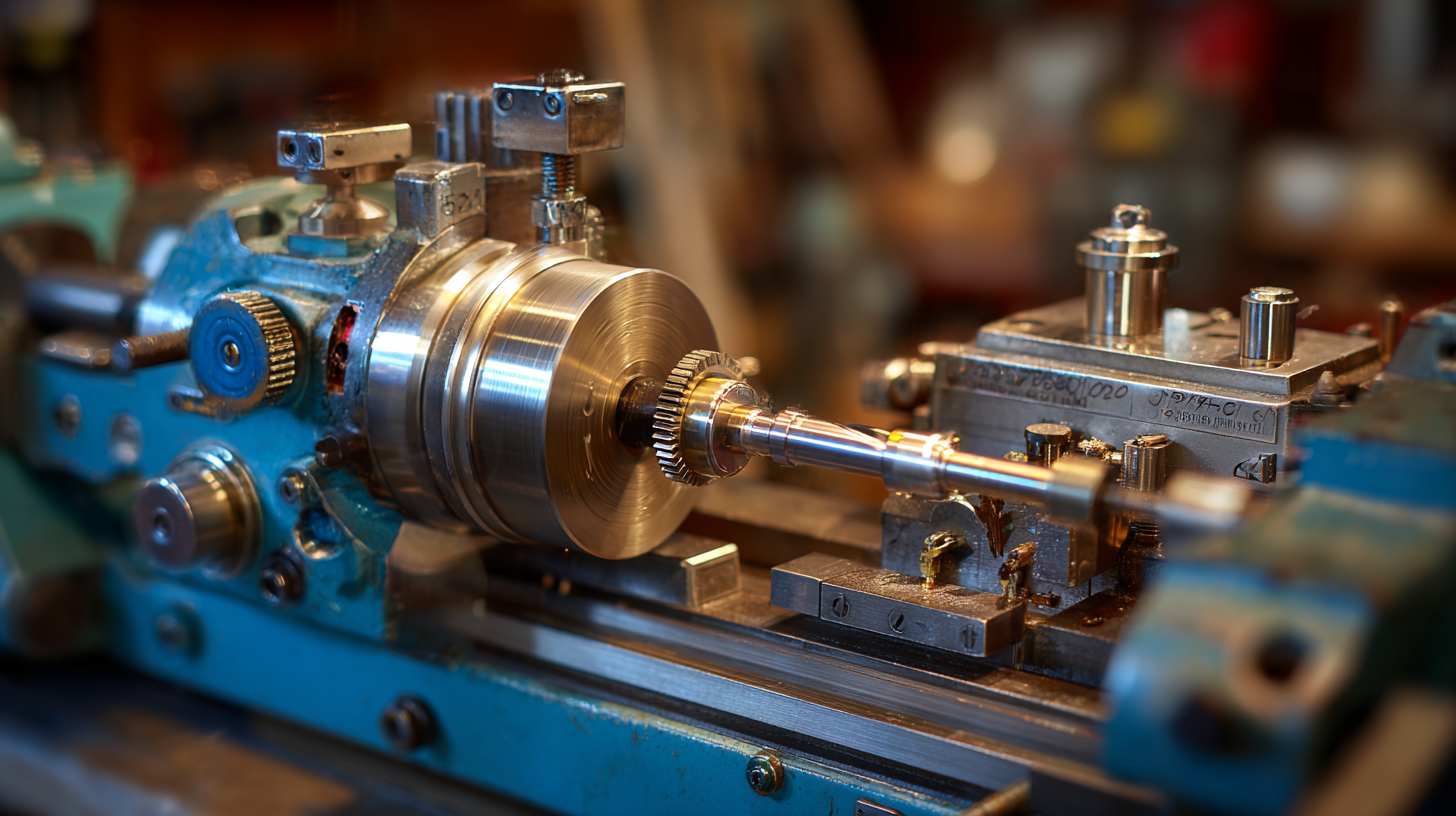

In the ever-evolving world of machining and manufacturing, the quest for the best lathe and milling machine options continues to captivate professionals and enthusiasts alike. As we dive into 2025 industry trends, it's essential to explore not only the conventional choices but also the innovative alternatives that are emerging in the market. This blog will highlight unique options that challenge traditional boundaries, offering insights into the latest advancements in technology and design. By examining these alternatives, we aim to provide a comprehensive understanding of how they can enhance efficiency and precision in various applications, ultimately empowering machinists to make informed decisions tailored to their specific needs.

Join us as we embark on this exploration of distinctive lathe and milling machine solutions that could redefine your machining experience.

Join us as we embark on this exploration of distinctive lathe and milling machine solutions that could redefine your machining experience.

Advantages of After-Sales Service in Lathe and Milling Machine Purchases

After purchasing a lathe or milling machine, the importance of after-sales service cannot be overstated. According to a report from the Machinery Institute, over 70% of manufacturing companies rate after-sales service as critical to their operational success. Effective support can significantly reduce downtime, ensuring that machinery remains functional and productive, as unplanned downtimes can cost businesses an average of $250,000 annually.

Additionally, robust after-sales service includes regular maintenance, training, and access to spare parts, which can greatly enhance the machine's longevity and performance. A study conducted by the Manufacturing Performance Institute found that companies that invested in comprehensive after-sales support reported a 30% increase in machine efficiency. This underscores the fact that choosing a lathe or milling machine is not solely about the initial purchase; the potential for sustained productivity heavily relies on the quality of the service provided post-purchase. Thus, businesses should carefully evaluate the after-sales offerings of suppliers when making equipment decisions to ensure they receive the full benefits of their investment.

Exploring Unique Alternatives to the Best Lathe and Milling Machine Options

This chart represents the average customer satisfaction ratings for different types of lathes and milling machines. It's essential for buyers to consider these ratings, along with after-sales service, when making a purchase decision.

Analyzing Maintenance Costs: The Hidden Factor in Machine Longevity

When selecting a lathe or milling machine, one critical yet often overlooked aspect is the maintenance costs associated with these machines. According to the 2023 Precision Machining Industry Report, maintaining high-quality equipment can account for up to 20% of the total cost of ownership. This statistic emphasizes that while the initial investment in a machine is significant, ongoing maintenance is equally crucial for ensuring long-term performance and reliability.

Evaluating unique alternatives to conventional lathes and milling machines becomes even more pertinent when considering the maintenance implications. Some specialized CNC machines, for instance, are designed with modular components that ease repair and maintenance, potentially reducing these costs. A study by the National Association of Manufacturers found that companies opting for more advanced technologies reported maintenance savings of 15-30% over a five-year period. This trend underscores the importance of not just the machine's purchase price but also its maintenance efficiency in contributing to overall operational success and machine longevity.

Emerging Technologies in Lathe and Milling Machines: What to Expect by 2030

As we stand on the cusp of a technological revolution in manufacturing, lathe and milling machines are poised for significant transformation by 2030. The emergence of smart technologies, including AI and IoT integration, is expected to redefine how these essential tools are operated. Manufacturers can expect real-time data analytics to monitor machine performance, reduce downtime, and facilitate predictive maintenance. This shift will not only enhance productivity but also minimize operational costs, making advanced machining more accessible to businesses of all sizes.

In addition to smart technologies, advancements in materials and design will bring innovative machining methods to the forefront. Additive manufacturing techniques combined with traditional subtractive methods could lead to hybrid machines capable of executing complex tasks that were previously thought impossible. For example, the incorporation of composite materials into the machining process will enable lighter yet stronger components. By 2030, machinists can anticipate a more versatile and efficient production environment where the boundaries of design and manufacturing continue to blur, leading to an era of unparalleled creativity and precision in machining.

Comparing Standard vs. Custom Machines: Efficiency and Cost Implications

When considering the efficiency and cost implications of standard vs. custom lathes and milling machines, it's essential to analyze not only the upfront costs but also the long-term operational expenses. Standard machines often have lower initial prices and are readily available, making them an attractive choice for many businesses. However, custom machines are designed to meet specific operational needs, potentially leading to greater efficiency and productivity over time. This tailored approach can offset higher purchase prices through reduced labor costs and increased output.

Tips for decision-makers include assessing production volume and product complexity when evaluating machine types. If you anticipate rapid scalability or unique product specifications, investing in custom machinery might provide a competitive edge. Additionally, consider energy efficiency ratings; modern standards for electric motors indicate that incorporating high-efficiency machines can substantially lower operating costs while enhancing overall performance.

Lastly, explore financing options or passive income streams to support your equipment investments. Generating additional income can help offset expenses associated with custom machinery, allowing for a more sustainable approach to scaling your operations while maintaining high efficiency.

Innovations in Customer Support for Precision Machinery: A Game Changer

The landscape of precision machinery has undergone significant transformations, particularly in customer support, which has become a pivotal factor in the industry. According to a recent study by ResearchAndMarkets, the global machining market is expected to grow at a CAGR of 6.2% from 2021 to 2026. One of the primary drivers of this growth is innovation in customer service offerings. Manufacturers are now adopting advanced technologies such as AI-driven chatbots and augmented reality for remote support, which drastically reduces downtime for businesses reliant on lathes and milling machines.

**Tip:** Always inquire about the support options available when purchasing machinery. Proactive companies will provide detailed information about their customer service availability and the technology in use.

Additionally, a shift toward real-time feedback and tailored customer experiences is reshaping the industry. Companies like Haas Automation have integrated user-friendly interfaces that facilitate hassle-free communication between users and support teams. This approach not only enhances user satisfaction but significantly prolongs the lifecycle of the machinery.

**Tip:** Implement regular training for your team on new technologies from your machinery supplier to maximize efficiency and utilize the latest support features effectively.

Exploring Unique Alternatives to the Best Lathe and Milling Machine Options

| Feature | Conventional Option | Innovative Alternative | Customer Support Features |

|---|---|---|---|

| Precision | ±0.01 mm | ±0.005 mm | 24/7 Remote Support |

| Material Versatility | Limited | Wide Range | Live Chat and Online Training |

| Setup Time | 1 hour | 15 minutes | Step-by-step Video Guidance |

| Energy Efficiency | Standard | Advanced Eco Mode | Dedicated Support Hotlines |

| Programming Interface | Basic | AI-Assisted | 24/7 Technical Assistance |