Understanding the Unique Features and Applications of the Best Measuring Equipment for Global Buyers

In the ever-evolving landscape of industrial technology, the demand for precise and reliable Measuring Equipment has become paramount for global buyers seeking to enhance efficiency and accuracy across various applications. According to a recent report by MarketsandMarkets, the global measuring equipment market is projected to reach $20.7 billion by 2025, growing at a CAGR of 6.1%. This growth underscores the critical role of measuring devices in sectors such as manufacturing, construction, and healthcare, where precision is non-negotiable. From digital calipers to advanced laser measuring tools, the diversity of available options reflects the specific needs of different industries. Understanding the unique features and applications of these tools can empower businesses to make informed decisions, optimize operations, and ultimately gain a competitive edge in their respective markets.

Unique Characteristics of Chinese Measuring Equipment in the Global Market

In the competitive global market, Chinese measuring equipment stands out due to its unique characteristics that appeal to international buyers. According to a report by MarketsandMarkets, the global measuring instruments market is projected to reach $24.2 billion by 2026, with a significant contribution from innovations in Chinese manufacturing. The advanced technology and cost-effectiveness of Chinese measuring devices, ranging from digital calipers to laser measuring tools, provide exceptional value for buyers looking to optimize quality and efficiency.

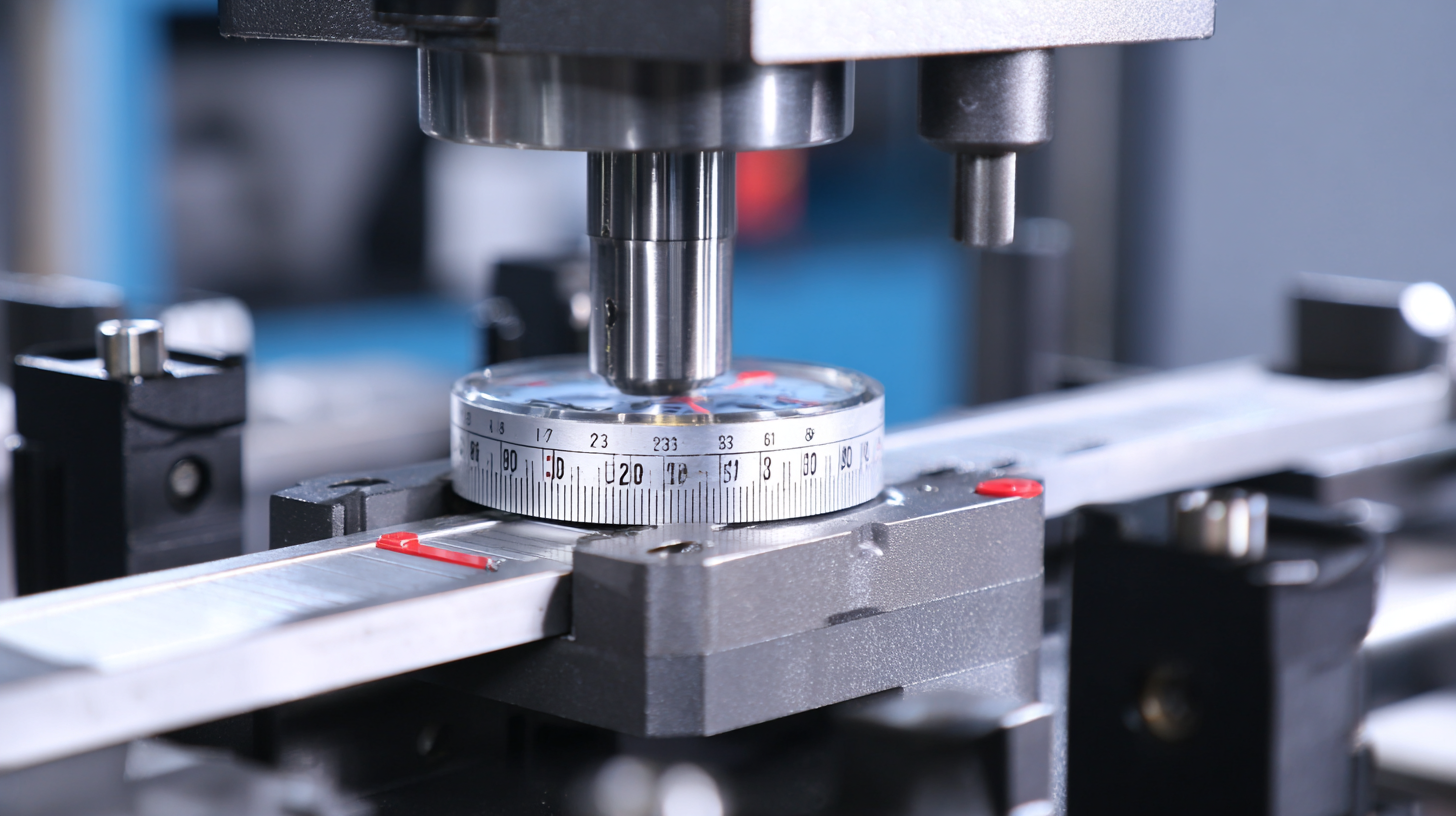

One of the notable features of Chinese measuring equipment is its emphasis on precision and reliability. For instance, recent studies indicate that China has improved its accuracy standards by investing in R&D and adhering to international quality standards, which is essential for competitive markets such as automotive and aerospace. Additionally, many Chinese manufacturers offer customization options, allowing global buyers to tailor equipment to their specific needs.

Tips: When selecting measuring equipment, consider manufacturers that provide detailed specifications and customer support. Additionally, assess the warranty and service options to ensure long-term reliability of your equipment. Finally, compare features and pricing with local alternatives to make an informed choice that fits your business requirements.

Key Applications of Measuring Equipment Across Various Industries

Measuring equipment is crucial across various industries, serving key applications that enhance productivity and ensure compliance with regulations. In the environmental sector, for example, advanced monitoring instrumentation is vital for tracking emerging pollutants. As legislation becomes more stringent, companies are increasingly turning to sophisticated measuring tools to analyze water and air quality, ensuring that they meet regulatory standards and minimize their environmental impact.

In manufacturing and production lines, accurate measurement devices play a significant role in quality control. Utilizing high-performance sensors allows businesses to monitor conditions such as pressure, temperature, and flow, ensuring efficiency and safety. As the trend towards automation and AI integration grows, these measuring devices not only support existing processes but also facilitate the adoption of new technologies, enhancing overall operational effectiveness.

Tips: When selecting measuring equipment, prioritize devices that offer real-time data analytics capabilities. This feature can significantly improve decision-making processes. Additionally, consider the scalability of the equipment, as industries evolve and expand, having adaptable tools can save costs and ensure long-term usability. Regular training on the latest measuring technologies can also empower your team to fully harness their potential.

Quality Standards and Innovations in Chinese Manufacturing

The evolution of measuring equipment in Chinese manufacturing reflects a commitment to quality standards and innovative practices. As global buyers seek reliable tools, manufacturers in China have adapted by implementing strict quality control measures. This includes adherence to international certification standards such as ISO, which ensures that products meet both safety and performance benchmarks. The integration of advanced technologies in production processes, like automation and precision engineering, has further enhanced the quality of output, making these products competitive on a global scale.

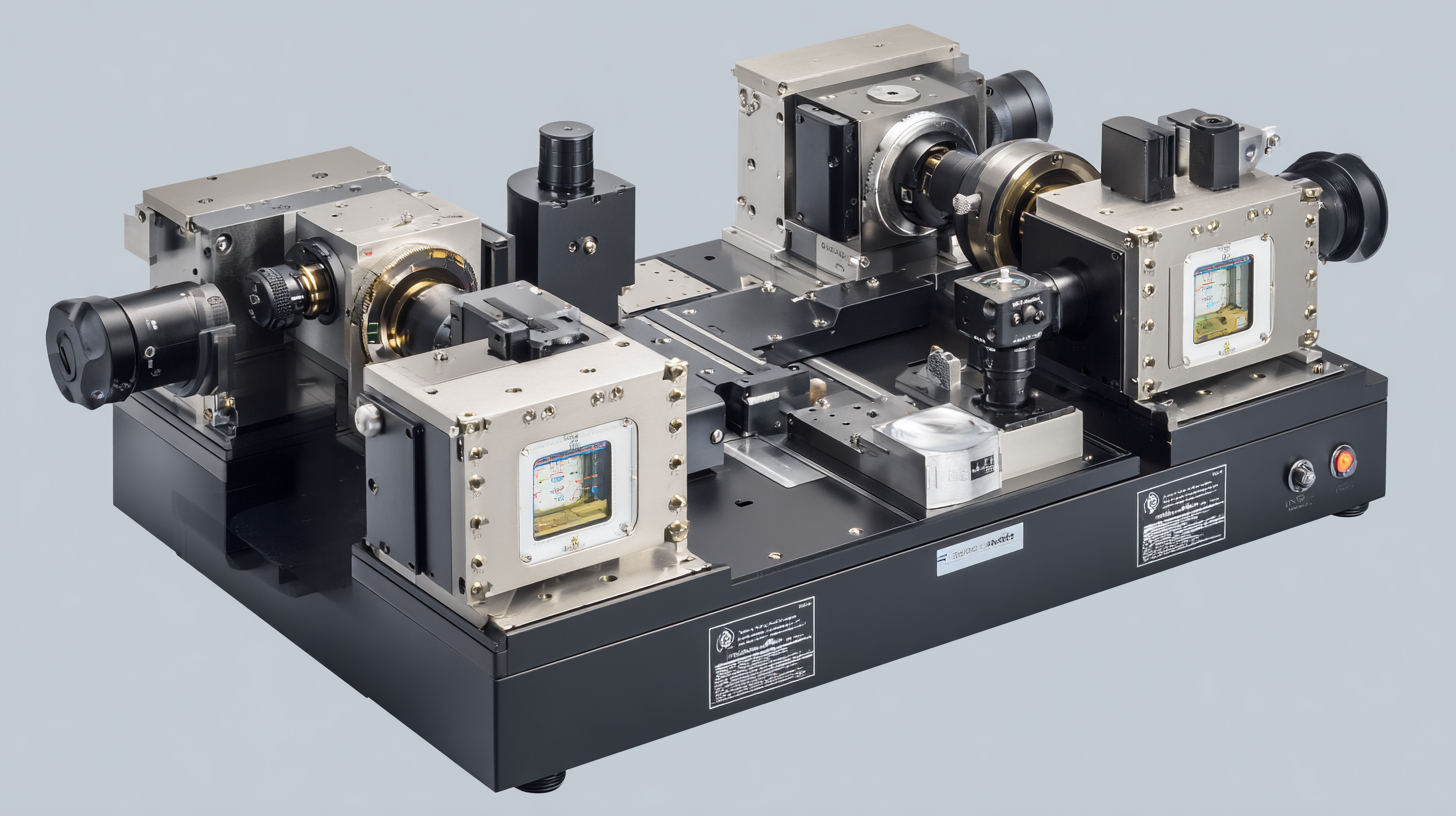

Moreover, innovations in manufacturing techniques not only improve the accuracy and efficiency of measuring equipment but also expand their applications across various industries. For instance, the use of smart technologies, such as IoT-enabled devices, allows for real-time data collection and analysis, providing users with enhanced insights into their operations. As these advancements continue to take shape, Chinese manufacturers are well-positioned to meet the demands of an increasingly discerning global market, solidifying their reputation as leaders in quality and innovation.

Global Buyers' Preferences for Measuring Equipment

The Impact of Export Strength on Global Supply Chains

The impact of export strength on global supply chains cannot be overstated, especially when it comes to the measuring equipment industry. As businesses strive for precision and efficiency, the quality and reliability of measuring instruments become critical factors influencing export dynamics. Countries with robust manufacturing sectors that produce high-quality measuring tools are better positioned to dominate international markets, ultimately bolstering their export capabilities. This creates a ripple effect—enhanced measurement standards lead to improved product quality, which in turn increases buyer confidence and stimulates demand globally.

Moreover, the interplay between export strength and global supply chains highlights the importance of technological innovation. Advanced measuring equipment not only ensures compliance with international standards but also facilitates smoother logistics and reduced lead times. Global buyers are increasingly seeking suppliers who can deliver precision instruments that support their own operational needs, establishing a symbiotic relationship. As economies evolve and trade barriers fluctuate, countries that prioritize the advancement of their measuring equipment will likely experience a distinct competitive advantage in the ever-changing landscape of global trade.

Understanding the Unique Features and Applications of the Best Measuring Equipment for Global Buyers - The Impact of Export Strength on Global Supply Chains

| Equipment Type | Measurement Range | Accuracy | Applications | Export Strength |

|---|---|---|---|---|

| Digital Multimeter | 0-1000 V, 0-10 A | ±0.5% | Electrical troubleshooting, Calibration | High |

| Laser Distance Meter | 0.2 - 100 m | ±1.5 mm | Construction, Surveying | Medium |

| Thermal Imaging Camera | -20 °C to 350 °C | ±2°C | Building inspection, Electrical maintenance | High |

| pH Meter | 0 - 14 pH | ±0.01 pH | Laboratory, Water quality testing | Medium |

| Calorimeter | 0 - 500 °C | ±0.3 °C | Material testing, Food industry | Low |

Trends Influencing the Future of Measuring Equipment in International Markets

The global measuring equipment market is undergoing significant transformation driven by technological advancements and changing customer needs. According to a report by Markets and Markets, the measuring equipment market is projected to grow from USD 23.87 billion in 2020 to USD 31.04 billion by 2025, at a CAGR of 5.6%. This growth is largely influenced by the rising demand for precision and accuracy in manufacturing processes, particularly in sectors like aerospace, automotive, and healthcare. As international markets expand, the push for high-quality measurement tools that comply with global standards becomes paramount.

Moreover, the integration of smart technologies such as IoT and AI into measuring equipment is reshaping the landscape. A survey conducted by Deloitte found that 61% of manufacturers are implementing smart sensors and connected devices to enhance operational efficiency. This trend not only streamlines data collection but also provides real-time analytics, which is essential for making informed decisions on a global scale. The adaptation of these innovative technologies signifies that future measuring equipment will not only offer precise measurements but also robust connectivity to meet the dynamic requirements of global buyers in various industries.